| Model | Temp. Range | Dimension (mm) | Shelves | Refrigerant |

|---|---|---|---|---|

| CTA600 | 2~8℃ | 600×530×730 | 2 | R134a |

| CTA900 | 2~8℃ | 900×530×730 | 2 | R134a |

| CTA1200 | 2~8℃ | 1200×530×730 | 2 | R134a |

Why Choose Commercial Curved Glass Food Display Cabinet CTA Series

Temperature adjustable

On the right side, there is a digital temperature control panel. The LED display screen shows the temperature value inside the cabinet in real time. The multi - function buttons support operations such as temperature adjustment, lighting control, and defrosting setting. The microcomputer intelligent control system has a temperature accuracy of ±0.5°C, ensuring stable cake freshness preservation effect.

Mobile convenience design

Four universal wheels are installed at the bottom, two of which have a brake locking function. The wheels are made of silent rubber material, ensuring no noise interference during movement. They have a strong load-bearing capacity, with each wheel capable of bearing 100 kilograms, facilitating the adjustment of the cake cabinet's position and cleaning.

Safety protection configuration

The back is reserved with a space for power cord storage to avoid potential safety hazards caused by wire entanglement. The bottom of the device is 120mm above the ground to prevent water accumulation and dust from entering. The overall use of black baking paint process is wear-resistant and scratch-resistant, maintaining the long-term beauty of the appearance of the commercial cake display cabinet.

Maintenance convenience

The radiator grille has a detachable design, which is convenient for daily cleaning and maintenance. The waterproof level of the control panel is IP54, making it suitable for commercial environment use.

Application Scenarios

Introduction to usage scenarios and functions

Heat dissipation system design

The back is equipped with a large - area black heat - dissipation grille. The rhombic mesh design ensures sufficient heat dissipation for the compressor. The heat - dissipation area reaches 0.8 square meters, effectively reducing the operating temperature of the equipment and extending the service life of the cake cabinet. The grille is treated with a dust - proof coating, which is easy to clean and maintain.

Stainless steel panel

Adopting the one-piece stamping and forming process in the factory to ensure that the panel has no gaps and no welding points, completely eliminating the rust Hidden dangercaused by dirt accumulation in the gaps. The food-grade 304 stainless steel material is carefully selected. The chromium and nickel alloy components in it form a dense oxide film, which can effectively resist the erosion of water vapor, cream stains and acidic substances generated during the cake display process. This enables the cake cabinet to always remain bright and new in a humid kitchen environment and under the usage scenario of frequent door opening and closing. It not only extends the service life of the equipment but also creates a high-end display space for delicate pastries.

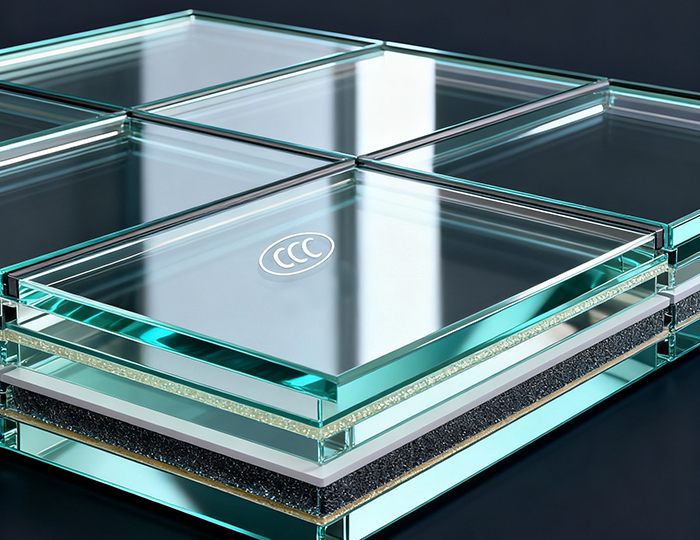

Low-E coated tempered glass

The double-layered insulating tempered glass is processed by high-temperature quenching at 600℃. Its impact resistance is 5 times that of ordinary glass. Even if it encounters an accidental impact, it will break into obtuse-angled particles, eliminating potential safety hazards. The Low-E coating technology endows the glass with excellent light transmittance, with a light transmittance of up to 92%. It can truly restore the color and texture of the cake, presenting each dessert like a work of art.

High-efficiency variable frequency compressor

Equipped with a high - efficiency variable - frequency compressor and adopting scroll compression technology, the refrigeration efficiency is increased by 30% compared with traditional compressors. It can accurately control the temperature inside the cabinet within the 2 - 8℃ golden fresh - keeping range in a short time. The running noise is as low as 38 decibels, and it is almost silent even in a quiet store environment, creating a comfortable shopping atmosphere for customers.

CAKE CABINET VIDEO

MORE

- FAQ

- Star Rating

- Product Brochure

- Inquiry Dynamics

What are the features of the CAT series cake cabinets?

How often should the refrigerant be replaced?

How to customize?

Bad reviews:

Click the button above to download the product manual and access comprehensive details about all product specifications, including models, sizes, capacities, and more. If you need assistance, please let us know which product you are interested in, and we will be happy to help!

Z*** sent an inquiry 4 days ago.

Q*** sent an inquiry 2 days ago.

C*** sent an inquiry 1 days ago.

K*** sent an inquiry 1 days ago.

R*** sent an inquiry 23 hours ago.

I*** sent an inquiry 21 hours ago.

K*** sent an inquiry 38 minutes ago.

O*** sent an inquiry 17 minutes ago.

N*** sent an inquiry 9 minutes ago.

B*** sent an inquiry just now.