Why Ice Cream Freezers Should Not Operate at Full Load?

In the context of ice cream storage and sales, the stable operation of ice cream freezers directly determines product quality and operating costs. The compressor, as the "heart" of the refrigeration system, plays a crucial role in this process. Many users mistakenly believe that full-load operation can improve storage efficiency, but they overlook the irreversible damage this causes to the compressor.

I. The Compressor: The "Power Core" of the Ice Cream Freezer's Refrigeration System

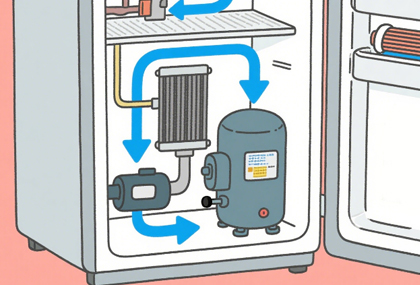

The refrigeration principle of ice cream freezers is based on the "refrigerant cycle": The compressor compresses refrigerants (such as eco-friendly refrigerants like R404A and R290), transforming them from a low-pressure gas state to a high-pressure gas state. Subsequently, the refrigerant releases heat and liquefies in the condenser, then passes through the capillary tube for throttling and pressure reduction, enters the evaporator to absorb heat inside the freezer, and finally returns to the compressor in a gaseous state, forming a closed-loop cycle. During this process, the compressor acts as the "power source," and its operating efficiency directly determines the temperature control accuracy and cooling speed inside the freezer.

For ice cream storage, the temperature inside the freezer needs to be stably maintained below -18°C, and the temperature fluctuation should be controlled within ±2°C. Otherwise, it is easy to cause problems such as ice crystal formation and deterioration of the ice cream's texture. The compressor is designed to operate in an "intermittent start-stop" mode: When the temperature inside the freezer exceeds the set value, the compressor starts cooling; once the set temperature is reached, the compressor stops, relying on the insulation layer to maintain a low temperature. This "start-stop cycle" not only ensures temperature stability but also allows the compressor to have the necessary rest time, avoiding continuous high-load operation. Full-load operation means forcing the compressor to work continuously for a long time, breaking the original design balance and causing damage to the compressor in multiple ways.

II. Three Core Hazards of Full-Load Operation to the Compressor

(I) High-Temperature Overload: Exceeding the Compressor's "Temperature Tolerance Limit"

When the compressor is running, it generates two types of heat: one is the mechanical friction heat from the motor operation, and the other is the compression heat released during the refrigerant compression process. Under normal operating conditions, the compressor's heat dissipation system (such as built-in fans and heat sinks) can promptly discharge the heat, maintaining the body temperature within a safe range of 80-100°C. However, during full-load operation, the compression frequency of the compressor increases significantly, reducing the residence time of the refrigerant in the compression chamber. As a result, the heat generated during the compression process cannot be fully dissipated, causing the body temperature to rise sharply.

When the body temperature exceeds 120°C, the insulating materials inside the compressor (such as the enameled wire insulation layer) begin to age and deteriorate, significantly reducing their insulation performance and making internal short circuits highly likely. If the temperature continues to rise above 150°C, the insulating materials may directly carbonize, leading to the complete failure of the compressor.

Additionally, high temperatures affect the physical properties of the refrigerant—excessive temperatures cause the refrigerant to vaporize prematurely in the compression chamber, resulting in a "liquid slugging" phenomenon. This means that the incompletely liquefied refrigerant liquid enters the compressor cylinder, colliding violently with the cylinder wall and causing mechanical failures such as cylinder wall wear and valve damage, severely affecting the compressor's service life.

(II) Lubrication Failure: Damaging the Compressor's "Wear Protection Barrier"

The normal operation of the compressor depends on its internal lubrication system. Lubricating oil not only reduces friction losses between moving parts (such as the crankshaft, piston, and bearings) but also plays a role in sealing and cooling, serving as the "protection barrier" for the long-term stable operation of the compressor. Under the designed operating mode, the lubricating oil is evenly distributed on the surfaces of each moving part through the splashing of the rotating crankshaft or the pressure delivery of the oil pump, forming a stable oil film and keeping the friction coefficient below 0.01, effectively reducing wear.

However, during full-load operation, the rotational speed of the compressor increases significantly, accelerating the relative speed between moving parts and significantly increasing the heat generated by friction, causing the temperature of the lubricating oil to rise. When the temperature of the lubricating oil exceeds 60°C, its viscosity decreases significantly, weakening the load-bearing capacity of the oil film. If the temperature exceeds 80°C, the lubricating oil may oxidize and deteriorate, producing impurities such as sludge and carbon deposits, which can clog the lubricating oil passages and lead to insufficient lubrication system oil supply.

At the same time, high temperatures cause the volatile components in the lubricating oil to evaporate, further reducing the quality of the oil film and resulting in "dry friction" between moving parts. Data shows that when the lubrication system fails, the wear rate of the compressor increases by 10-20 times, and the service life of key components such as bearings and pistons may be reduced from 5-8 years to 1-2 years, significantly increasing equipment maintenance costs.

(III) Motor Overload: Exceeding the Compressor's "Power Capacity Range"

The core driving component of the compressor is an asynchronous motor, and its power design matches the refrigeration capacity requirements of the ice cream freezer, usually following the "1.2 times safety factor" principle. That is, the rated power of the motor is 20% higher than the maximum actual operating power to cope with short-term load fluctuations. During normal operation, the working current of the motor remains at 70%-80% of the rated current, operating in a low-load, high-efficiency state. During full-load operation, as the freezer needs continuous cooling, the compressor constantly increases the compression frequency, causing the motor's working current to rise continuously, even exceeding 1.5 times the rated current and entering an "overload operation" state.

When the motor is overloaded, the copper loss (I²R) of the stator winding increases proportionally to the square of the current, causing the winding temperature to rise rapidly. When the winding temperature exceeds 130°C, its insulation class drops from Class A to Class B, significantly reducing its insulation performance. If it remains in an overloaded state for a long time, the winding temperature may exceed 155°C, causing the insulation layer to burn out and resulting in a short circuit in the motor.

In addition, overload causes the power factor of the motor to decrease from the normal 0.85-0.9 to below 0.7, reducing the effective output power of the motor and creating a vicious cycle of "high current, low efficiency"—the motor consumes more electrical energy but cannot provide sufficient cooling power, not only increasing electricity bills but also further exacerbating motor wear. Experimental data from a refrigeration equipment testing institution shows that when the compressor operates at full load for a long time, the failure rate of the motor increases by 3-5 times, and the difficulty and cost of maintenance after failure increase significantly.

III. Scientific Operation: Dual Strategies for Ensuring Compressor Lifespan and Ice Cream Quality

Based on the above analysis, the scientific operation of ice cream freezers needs to follow the "non-full-load" principle, starting from both equipment maintenance and usage habits to balance storage needs and compressor protection:

(I) Control Storage Quantity to Avoid "Overcapacity Operation"

The designed storage capacity of ice cream freezers is usually indicated in the product manual. Users should strictly follow the principle of "the storage quantity should not exceed 80% of the rated capacity." On the one hand, leaving 20% of the space ensures the normal circulation of cold air inside the freezer, avoiding local temperature increases caused by item accumulation and reducing the start-stop frequency of the compressor. On the other hand, a reasonable storage quantity reduces the load on the refrigeration system, allowing the compressor to maintain a "low-frequency, long-interval" operation state and reducing the risks of high temperature and overload.

(II) Regular Maintenance to Ensure Lubrication and Heat Dissipation

Regularly check the compressor's lubrication system, and replace the lubricating oil every 6-12 months to ensure that the viscosity and cleanliness of the lubricating oil meet the requirements. At the same time, clean the dust and debris on the compressor's heat sinks to ensure the ventilation efficiency of the heat dissipation system and prevent the body temperature from rising due to poor heat dissipation.

(III) Reasonable Temperature Setting to Reduce Load Fluctuations

Set the temperature inside the freezer between -18°C and -22°C according to the storage requirements of ice cream, avoiding forcing the compressor to operate at full load in pursuit of "lower temperatures."

Note that reducing the frequency and duration of door openings can prevent cold air loss, avoid frequent compressor starts, and reduce load fluctuations of the motor.

Although full-load operation may seem to improve storage efficiency, it actually causes irreversible damage to the compressor from three aspects: high-temperature overload, lubrication failure, and motor overload, ultimately leading to frequent equipment failures and increased maintenance costs. Only by following scientific operating principles, reasonably controlling the load, and conducting regular maintenance can the compressor operate stably for a long time, ensuring both the quality of ice cream and reducing operating costs, achieving a win-win situation of "extended equipment lifespan" and "improved operating efficiency."

Most popular More «

-

What are the models available for the Cooluma bread refrigerator with two shelves?

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?

-

Ideal temperature and temperature control points of cake cabinet