Ideal temperature and temperature control points of cake cabinet

The ideal temperature of the cake cabinet is 2-8 degrees Celsius. In the actual scene, it needs to be determined according to the ambient temperature, which is affected by different ambient room temperature. Secondly, it is related to the type of food. Different types of cakes have different temperature settings, which also reflects the importance of temperature control.

1. Why is the "ideal temperature" crucial for cake cabinets? —— First, clarify the core premise

Whether it's the display case in a bakery or the refrigerator for storing cakes at home, temperature control directly determines the taste, shelf life, food safety, and appearance stability of cakes. This is not a subjective judgment, but based on the physical and chemical properties of cake ingredients:

Cream-based or mousse cakes: These contain substantial amounts of animal cream, light cream, or vegetable cream. Such ingredients tend to soften and collapse at temperatures above 10°C, melt rapidly at 20°C, and see bacterial growth accelerate dramatically (for instance, Listeria bacteria multiply 5-10 times faster in the 'dangerous temperature zone' of 8-15°C compared to low-temperature environments), posing a direct threat to food safety.

Qing-style sponge cake: Though lacking cream, its porous structure readily absorbs moisture from the air. Excessive heat accelerates moisture loss, resulting in a dry and hard texture, while temperatures below 0°C may cause tissue damage, leading to crumbling and a mushy texture after thawing.

Cheese / Cheese cake: As a fermented dairy product, cheese needs to be kept at a stable low temperature to inhibit excessive fermentation of lactic acid bacteria and avoid fat precipitation. Temperature fluctuations will cause cracks on the surface of the cake and rough texture.

Therefore, "ideal temperature" is not a single value, but a "temperature range" that is precisely matched to the type of cake, which is the consensus of all baking practitioners and food safety regulations.

2. Categorized by cake type: Ideal temperature range for cake cabinets (with professional evidence)

The varying ingredient compositions of different cakes determine their distinct storage temperature requirements. The following temperature standards are based on authoritative and practical references including GB 2716-2018 National Food Safety Standard for Vegetable Oils, Hygienic Specifications for Storage and Transportation of Baked Goods, and professional recommendations from the International Baking Institute (IBIE).

1. Cream / Mousse / Ice Cream Cake: 0-5℃, with the core technology being "freshness preservation + antibacterial"

This type of cake is the "key protected object" of the cake cabinet, and the ideal temperature needs to meet three requirements at the same time: inhibit bacterial reproduction, maintain the form of cream, and avoid water condensation.

Scientific evidence: According to the "National Food Safety Standard-General Rules for Storage and Transportation of Refrigerated and Frozen Foods", the safe refrigeration temperature for animal-derived cream is 0-4℃. Within this range, common pathogenic bacteria (such as Salmonella and Staphylococcus aureus) reproduce at a rate less than 1/20th of their normal temperature growth. Additionally, 0-5℃ helps maintain the cream's "soft and non-sagging" texture. Below 0℃, the cream may develop a granular texture due to frost damage, while above 5℃, it becomes softened and deformed, affecting its visual appeal.

Practical tip: For cakes with fresh fruits (e.g., strawberries or mangoes), keep the temperature between 2-4°C to prevent freezing damage (blackened skin) or spoilage (strawberries stored above 5°C will lose freshness from 3 days to 1 day).

2. Cheese Cake: 2-7℃, balancing 'textural quality and fermentation stability'

The key ingredient in cheesecake is cream cheese, which requires an ideal temperature that balances 'stopping over-fermentation' with 'keeping the texture fluffy.'

Scientific rationale: During fermentation, cream cheese produces lactic acid. The 2-7℃ temperature range slows lactic acid bacteria metabolism, preventing excessive acidity (resulting in a 'stringy taste'). This optimal range also stabilizes the cake's fat structure, avoiding both' hard texture 'from low temperatures and' fat separation (oiliness on the surface)' from high temperatures.

Industry case: The cheese cake display cabinets of international chain baking brands (such as Yizhido and 85℃) are all set at a constant temperature of 3-5℃, which can not only ensure that the taste of the cake remains unchanged for 3-5 days in cold storage, but also avoid surface cracks caused by temperature fluctuations.

3. Qi Feng / Sponge / Pound Cake (No Cream): 5-10℃, with a focus on 'moisturizing and preventing hardening'

These cakes use non-perishable dairy products that require less stringent temperature control, but care must be taken to prevent moisture loss and tissue frostbite.

Ingredient Characteristics Analysis: The sponge-like structure of chiffon cake makes it particularly sensitive to temperature. When stored below 5°C, moisture condenses into tiny ice crystals that melt upon thawing, causing texture loss. Conversely, temperatures above 10°C accelerate moisture evaporation. While chiffon cake stored at room temperature loses up to 15% of its moisture in 24 hours, maintaining 5-10°C keeps moisture loss under 5%, preserving its signature soft and fluffy texture.

Note: If the cake surface has sugar frosting (such as butter frosting), the temperature should be controlled at 5-8℃ to avoid the sugar frosting softening and deforming (when the temperature is higher than 8℃, the butter frosting will melt easily and the "flowing frosting" phenomenon will occur).

3. Don't Just Focus on Temperature! 3 Key Details for Achieving "Ideal Temperature Control" (Expert Insights)

Even with the ideal temperature set, neglecting the cake cabinet's temperature control features will still compromise the cake's quality. These insights stem from over a decade of hands-on experience at a professional bakery, ensuring their reliability.

1. Temperature control: The temperature difference between different areas in the cabinet should not exceed 2℃

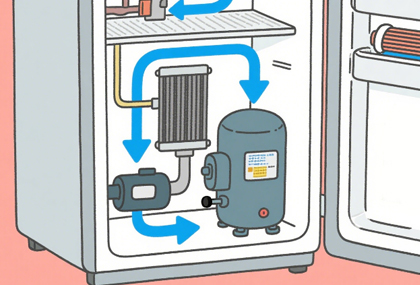

A qualified cake cabinet must maintain "uniform cooling" — in some outdated direct-cooling models, temperatures near the evaporator may drop to 0°C, while corners far from it can reach 7°C. This temperature disparity causes cakes in the same cabinet to "some develop frost damage while others soften".

Expert advice: Opt for a "wind-cooled frost-free" cake cabinet, which maintains uniform temperature through fan circulation with temperature fluctuations under 1℃. For direct-cooling cabinets, clean the evaporator frost weekly and avoid placing cream cakes directly beneath it.

2. Humidity control: Maintain relative humidity at 60%-70%

Temperature and humidity are the 'golden duo': if the humidity is below 60%, the chiffon cake will lose water quickly and dry out; if the humidity is above 70%, the surface of the cream cake will easily condense water droplets, resulting in melted cream and poor texture.

Industry standard: The Technical Requirements for Display Cabinets of Baked Goods clearly stipulates that the relative humidity of cream cake display cabinets should be controlled at 65%±5%. Some high-end display cabinets have built-in "humidity adjustment function" to automatically replenish water (such as through built-in humidifier) to avoid humidity fluctuations.

3. Temperature fluctuation: The set temperature is restored within 15 minutes after opening and closing the door

The frequent opening and closing of cake cabinets during peak hours in bakeries can cause a sudden rise in temperature inside the cabinets. If the temperature is restored for too long (for example, more than 30 minutes), it will accelerate the softening of cream and the reproduction of bacteria.

Purchase Tips: When selecting a cake cabinet, prioritize its cooling speed. Premium commercial models (e.g., Haier and Aucma series) can restore the set temperature within 10-15 minutes after door operation. Additionally, installing thermal curtains on the cabinet doors helps minimize cold air loss during door movement.

4. Common Pitfalls: Avoid Letting 'Temperature Control Errors' Ruin Your Cake (with Solutions)

Many bakers fall into the trap of improper temperature settings, which increases cake spoilage. The following common mistakes are based on real industry feedback, with corrective measures referencing the National Food Safety Standard for Hygiene of Pastries and Bread.

|

Common Misconceptions |

harm |

Professional Correction Plan |

|

All cakes are set to 0°C. Lower temperature is safer. |

The cake has frost damage and the cream has granules |

Store by category: cream/mousse in the 0-5℃ zone, sponge/foam in the 5-10℃ zone. Use partitions or separate drawers for organization. |

|

Turn off the power of the cake cabinet at night to save power |

When the temperature rises to room temperature, the bacteria multiply in large numbers and the cake needs to be scrapped the next day |

Select the "Primary Energy Efficiency" cake cabinet, which can activate "Energy-saving Mode" at night (raising temperature by 1-2℃) instead of power-off. |

|

Only check the display temperature without calibrating the actual temperature |

Display screen shows actual temperature deviation (e.g., 3℃ vs. 5℃), cream softening |

Calibrate the temperature with a professional thermometer (0.1℃ accuracy) once a month. If the deviation exceeds 1℃, contact after-sales service to adjust the refrigeration system. |

5. Scientific temperature control = reduce loss + improve reputation

The 'ideal temperature' for a cake cabinet isn't a fixed number, but a system engineering that combines' precise matching by category 'with' detailed temperature control.' Remember the core principle:

Cream / Mousse / Ice Cream Cake: 0-5℃, prevents softening and bacterial growth.

Cheese cake: 2-7℃ to preserve texture and ensure stable fermentation.

Chiffon sponge cake: 5-10℃ to prevent drying, hardening, and freezing damage.

We need to understand that by combining the details of "uniform temperature control, humidity coordination, and reduction of fluctuations", the cake loss rate can be reduced from 8%-10% to less than 2%, and the consumer reputation can be improved through stable quality--this is one of the core differences between professional bakeries and ordinary shops.

Most popular More «

-

Ideal temperature and temperature control points of cake cabinet

-

Which Cooluma compact commercial cake display cabinet is the best?

-

What are the procedures required for the certification of food display cabinets?

-

Aims to be a global supplier of commercial cold chain equipment, Cooluma

-

Best Automatic Refrigerated Display Cabinet Series

-

Is Cooluma a Professional Cold Chain Equipment Service Provider?

-

Where Lies the Value of the Best Cake Display Showcase?

-

What are the advantages of a room-temperature cake display cabinet?

-

How much does a 120L bread cabinet cost?

-

Functions and Maintenance Details of Coffee Display Cabinets