Technical Parameters and Solutions for Commercial Cake Chillers

In the baking business, the technical performance of cake chillers directly affects the preservation effect, display quality, and operational efficiency of cakes. Users often encounter pain points such as cake spoilage due to unstable temperature control, poor display affecting consumer decisions, limited SKU expansion caused by irrational space utilization, and increased maintenance costs due to insufficient equipment durability.

I. Space and Shelf Technology: Solving the Pain Point of "Low Display Efficiency"

Bakery owners commonly report issues with cake chillers, such as "fixed shelf height that cannot accommodate cakes of different sizes," "insufficient shelf load - bearing capacity leading to deformation," and "unreasonable space layout causing area waste." For example, an 8 - inch cheesecake cannot be placed due to a shelf height of only 15cm, or multi - layer cakes tilt due to poor shelf load - bearing, which not only affects the display effect but also limits the expansion of product varieties.

Technical Parameters and Solutions

From a technical perspective, the shelf design of professional cake chillers needs to meet three core indicators: height adjustability + load - bearing stability + space utilization. The shelf - fixing structure adopts a stepped buckle structure, supporting shelf height adjustment in 5cm increments, with an adjustment range from 10 - 30cm, suitable for all sizes of cakes from 4 - inch small cakes to 12 - inch multi - layer cakes.

The shelf is made of 304 stainless steel plate (1.2mm thick), combined with "reinforced metal hinges." Each shelf can bear a load of up to 15kg, stably supporting five 8 - inch cakes (about 2.5kg each), fully meeting the requirements of high - frequency access in commercial scenarios.

Meanwhile, the internal space of the chiller follows the golden ratio layout. The width, depth, and height ratio ensure uniform display area on each layer, avoiding situations like "wasted upper space and crowded lower space," achieving the maximum display capacity within an area of 1.2m².

II. Temperature Control and Refrigeration Technology: Solving the Problem of "Ineffective Cake Preservation"

Cake preservation requires extremely high temperature precision: mousse cakes need a slightly frozen environment of - 2 to 5℃, and cheesecake requires a refrigerated environment of 2 to 8℃. A temperature fluctuation of more than ±1℃ will deteriorate the taste of the cake and shorten its shelf life.

In addition, users also face pain points such as "loud refrigeration noise affecting the store environment" and "low refrigeration efficiency, taking 2 hours to reach the set temperature after startup."

Technical Parameters and Solutions

Precise Temperature Control System: Using a dual - probe temperature sensor (cabinet air probe + evaporator probe), combined with a "PID intelligent temperature control algorithm," the temperature fluctuation is controlled within ±0.5℃, fully meeting the preservation temperature requirements of various cakes. For example, in a stable environment of 2 - 8℃, the shelf life of cheesecake can be extended by 3 - 5 days, and mousse cakes maintain their shape longer in a - 2 to 5℃ slightly frozen environment.

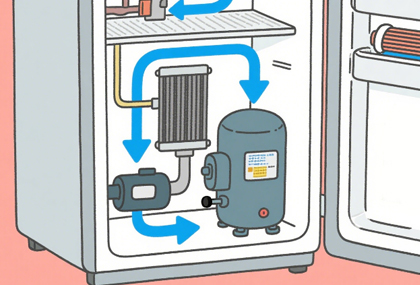

Efficient Refrigeration Components: The core compressor is an R290 environmentally friendly refrigerant compressor (input power 180W, energy efficiency grade 1), combined with a "fin - type evaporator (heat transfer area 1.2㎡)," achieving a fast refrigeration effect of "reaching the set temperature within 40 minutes after startup." Compared with traditional compressors, the thermal efficiency of R290 refrigerant is increased by 20%, and it is fluorine - free and environmentally friendly, in line with the green development trend of commercial equipment.

Noise Reduction Technology Optimization: To address the noise issue, a dual noise reduction solution of shock - absorbing base + sound - absorbing cotton wrapping is adopted. A "nitrile rubber shock - absorbing pad (60 Shore A hardness)" is installed at the bottom of the compressor to reduce vibration transmission; the interior of the cabinet is filled with "high - density polyester fiber sound - absorbing cotton (20mm thick)," controlling the operating noise below 40 decibels (equivalent to normal conversation volume), without interfering with the store's operating environment.

III. Display and Sealing Technology: Overcoming the Pain Points of "Insufficient Visual Appeal" and "Cooling Loss"

Typical user feedback includes issues such as "poor glass door light transmission causing cake color distortion" and "poor glass door sealing leading to condensation and cooling loss." For example, a beautifully decorated artistic cake looks dull due to low glass light transmittance, or customers cannot see the cake details clearly due to glass door condensation, directly affecting purchasing decisions. At the same time, cooling loss caused by poor sealing makes the compressor start frequently, increasing power consumption and shortening the equipment's lifespan.

Technical Parameters and Solutions

High - Transparency Glass System: Adopting double - layer hollow tempered glass (8mm thick), with a light transmittance of up to 92% (only 75% for ordinary glass), and using "Low - E coating technology" to reduce infrared heat entry. It can clearly display the color and details of the cakes while reducing the interference of external heat on the internal temperature of the chiller. The high - transparency glass allows a clear view of the cream texture and piping details of the cakes, greatly enhancing visual appeal.

Sealing Structure Design: The glass door is equipped with food - grade silicone seals (cross - sectional size 10mm×8mm) around it, ensuring airtightness when closed through a three - layer redundant sealing design. Tests show that this sealing structure can reduce the cooling loss rate by 35% and decrease the average daily startup times of the compressor by 4 times. It not only saves electricity (reducing about 50 kWh of monthly consumption) but also extends the compressor's lifespan by 2 - 3 years. Meanwhile, the "anti - condensation coating" on the glass door prevents condensation when the ambient humidity ≤85%, ensuring a clear display effect at all times.

IV. Structure and Durability Technology: Solving the Pain Points of "Easy Equipment Damage" and "Difficult Maintenance"

Cake chillers in bakeries need to be used frequently for a long time. Users often encounter problems such as "loose shelf fixing parts," "peeling and corrosion of the cabinet surface," and "rusted and stuck hardware parts," which not only increase maintenance costs but may also cause cake spoilage (such as temperature control failure) due to equipment malfunctions.

Technical Parameters and Solutions

Cabinet Structure Reinforcement: Using a cold - rolled steel plate main body (1.5mm thick) + surface electrostatic powder coating treatment, with a powder coating layer thickness of 80μm and a salt spray resistance test exceeding 480 hours (the industry standard is 240 hours), effectively resisting corrosion from water vapor and sugar in the baking environment, ensuring no rust or peeling on the cabinet surface after long - term use.

Durable Hardware Design: Hardware parts such as shelf - fixing ladder strips and hinges are all made of 304 stainless steel material, combined with an "anti - loosening thread design," capable of withstanding ≥100,000 opening/closing/ adjustment operations without loosening. The "bite depth" of its metal buckle is ≥5mm, maintaining stability during frequent shelf adjustments and preventing shelf tilting due to loose fixing parts.

Easy Maintenance Design: The refrigeration system adopts a modular layout. Core components such as the compressor and evaporator can be quickly disassembled and maintained through the front maintenance port. Vulnerable parts (such as seals and lighting tubes) can be replaced without professional help; the shelves adopt a quick - release design and can be directly removed for cleaning, solving the problem of difficult - to - clean shelves in traditional cake chillers.

V. Specifications and Scenario Technology: Solving the Pain Point of "Insufficient Scenario Adaptability"

Bakeries of different scales (such as private studios, community stores, chain brands) have diverse requirements for the size and functions of cake chillers. Users often waste space or lack functionality due to "choosing the wrong specifications" (for example, a small store choosing a large chiller causes crowded operating space, while a large store choosing a small chiller results in insufficient display capacity).

Technical Parameters and Solutions

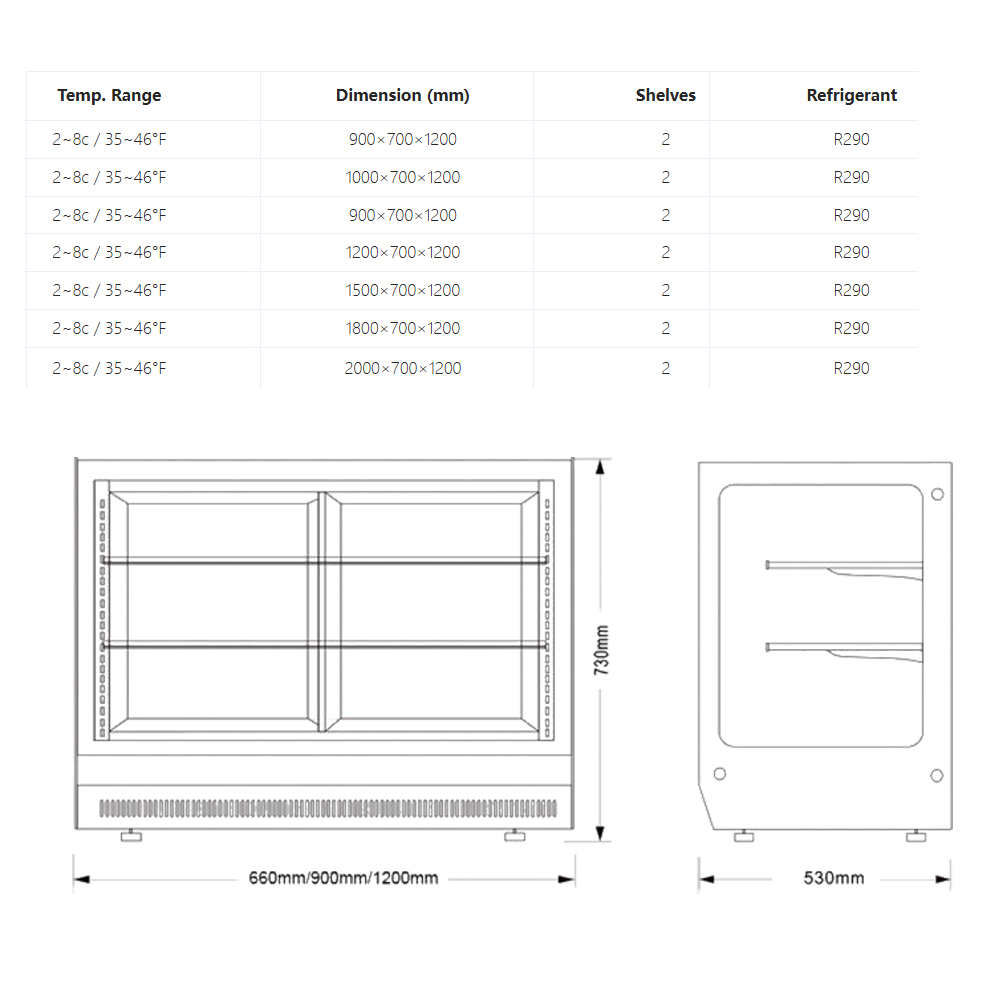

This series of cake chillers offers five different specifications, with widths ranging from 900 - 1500mm and heights from 1200 - 1600mm, precisely adaptable to various scenarios:

Private baking studios can choose a small chiller with a width of 900mm and a double - layer design to meet the display needs of small batches and multiple varieties.

Community stores are suitable for a medium - sized chiller with a width of 1200mm and a three - layer design, balancing display capacity and space occupation.

Chain brands can choose a large chiller with a width of 1500mm and multiple layers to achieve centralized display of multiple SKUs.

At the same time, for customization requirements, this series supports non - standard size customization + functional module selection (such as adding a defogging function or changing the lighting color temperature). Through a modular technical architecture, low - cost customization is achieved to meet the personalized needs of different brands (such as brand color powder coating, exclusive logo).

Conclusion: Practical Logic for Technical Selection

The technical selection of professional cake chillers should focus on pain point matching + parameter practicality. For baking professionals, the following technical indicators should be given priority:

Temperature control accuracy (≤±0.5℃) and refrigeration efficiency (cooling time ≤1 hour after startup);

Glass light transmittance (≥90%) and sealing performance (cooling loss rate reduced by more than 30%);

Shelf adjustment range (≥10 - 30cm) and load - bearing capacity (≥15kg per layer);

Equipment durability (salt spray resistance test ≥480 hours) and maintenance convenience (modular design).

Only by comprehensively judging these technical parameters based on actual operational pain points (such as preservation period, display effect, operating costs) can one select a truly suitable cake chiller and avoid usage problems and cost waste caused by inconsistent technical parameters.

Most popular More «

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?

-

Ideal temperature and temperature control points of cake cabinet

-

Which Cooluma compact commercial cake display cabinet is the best?

-

What are the procedures required for the certification of food display cabinets?

-

Aims to be a global supplier of commercial cold chain equipment, Cooluma