Why Are All-Glass Display Cases So Expensive?

Step into a luxury boutique in the city centre, and you'll find millennia-old artefacts displayed within fully transparent glass cases. These cases separate the relics from visitors without compromising the viewing experience. Yet when inquiring about the price of such display units, quotations in the five-figure or even six-figure range often prove astonishing — why does a mere ‘glass box’ command such a premium? In truth, the cost of all-glass display cases stems not from the ‘glass’ itself, but from the combined factors of material quality, precision craftsmanship, functional innovation, and market positioning.

I. High Material Costs

These cabinets employ specially treated materials far exceeding ordinary building glass. The mainstream ‘ultra-clear glass’ (also known as ‘low-iron glass’) used in 2025 contains merely one-tenth the iron content of standard glass, achieving light transmittance exceeding 91.5%. This minimises the inherent green tint of glass, ensuring displayed items appear in their true colours.

The production of this glass is exceptionally challenging, requiring complex processes such as raw material purification and precise temperature control. Its production cost per tonne is 30%-50% higher than that of ordinary float glass. Taking common 8mm-thick ultra-clear glass as an example, the procurement price per square metre is approximately $25.2, whereas ordinary glass of the same thickness costs only around $3.5, representing a price difference of threefold.

To ensure safety and durability, ultra-clear glass must undergo tempering. This process involves heating the glass to over 600°C before rapidly cooling it with cold air, creating a surface layer of compressive stress. This enhances compressive strength to five times that of ordinary glass and increases impact resistance by threefold. Crucially, upon breakage, it shatters into small, blunt-edged fragments, preventing injury from sharp shards. Tempering carries a certain scrap rate (industry average approximately 8%-12%). For larger glass dimensions or complex shapes, this rate can exceed 20%, further elevating material costs.

Beyond glass, the cost of hardware fittings is also significant. Components such as display cabinet connectors, load-bearing brackets, and hinges must simultaneously meet three critical requirements: load-bearing capacity, rust resistance, and concealed installation. These are typically manufactured from 304 stainless steel or aerospace-grade aluminium alloy. Taking a 1.2-metre display cabinet as an example, hardware components alone cost $42-$70. Imported hinges with damping mechanisms can exceed $28 per set – 5-8 times the price of standard hinges.

II. Complex Craftsmanship Drives Up Labour Costs

Display cabinets that combine aesthetic appeal with practicality rely on a series of highly demanding craftsmanship techniques, the investment in which is often overlooked. The most critical of these is the ‘seamless splicing’ technique, which requires the gap between two glass panels to be less than 0.5mm. This is achieved using imported invisible adhesive, applied within a dust-free workshop. Workers must repeatedly calibrate using laser levellers, with each metre of joint taking approximately 1.5 hours. Should air bubbles or uneven gaps occur, the entire section requires reworking.

Compared to the standard sealing process for ordinary glass cabinets (taking 15 minutes per metre), seamless splicing incurs over six times the labour cost and necessitates precision calibration equipment worth tens of thousands of yuan.

Edge finishing represents another significant cost driver. Glass edges undergo ‘precision grinding and polishing’ through repeated diamond wheel processing (4-5 passes) to achieve a mirror-like finish. This eliminates sharp-edge hazards while enhancing overall aesthetic quality.

These processes require skilled operators, with each square metre taking approximately one hour to polish at a processing cost of around $11.2. Standard glass display cabinets undergo only basic edge grinding, costing merely $2.1 per square metre. Some premium display units further employ ‘rounded corner processing,’ where dedicated grinding machines transform right angles into 5-10mm radius curves, increasing processing costs by 30%.

Customisation demands further elevate costs, requiring design adjustments based on the client's displayed items and spatial dimensions. Take bakery display cabinets as an example: shelf heights must be tailored to food dimensions, glass inclination adjusted according to exhibition lighting angles, and even space reserved for installing temperature and humidity control equipment. The entire design process takes 3-5 working days, involving specialised tasks such as structural design and optical simulation. Design fees typically account for 10%-15% of the total price. Should clients request specialised shapes (e.g., curved or trapezoidal), bespoke moulds must be custom-made. A single mould can cost thousands of dollars and is only usable for one order, leading to significant mark-ups for small-batch production.

III. Functional Upgrades Drive Cost Increases

The modern all-glass display cabinet, serving as an integrated entity for protection, exhibition, and interaction, is a key factor in escalating costs.

Structural load-bearing design exemplifies this: to accommodate multi-tiered displays, shelf glass must possess sufficient load capacity. Typically, 12-15mm thick tempered ultra-clear glass is employed, while premium cabinets may utilise laminated glass (two panes bonded with PVB interlayer). This ensures glass remains intact upon breakage, achieving load capacities of 80kg/m². This laminated glass costs 2.5 times more than single-layer tempered glass and requires specialised processing equipment, further increasing expenses.

Optical optimisation features also demand additional investment. To prevent glare from direct lighting, some display cabinets feature an ‘anti-glare coating’ applied to the glass surface. This coating utilises nano-scale silica materials applied via vacuum deposition onto the glass surface, reducing glare rates to below 10%. However, the coating costs approximately $8.4–14 per square metre, and any imperfections during deposition necessitate reprocessing.

For display cases housing jewellery, watches and similar items, a ‘directional lighting system’ is fitted. This combines LED light strips with light guides to ensure even illumination of the displayed items, accounting for approximately 15%-20% of the display case's total cost.

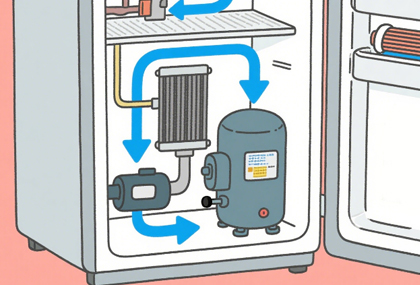

Costs for specialised protective features: Commercial all-glass display cabinets frequently require integrated constant temperature and humidity systems. Utilising high-precision sensors, these systems monitor the internal environment in real-time, maintaining temperatures within 6±2°C and humidity at 50%±5%. This prevents food items from becoming damp or drying out. Core components (such as imported humidity sensors and micro-compressors) cost approximately $420-$700. Furthermore, seamless integration with the display cabinet structure is essential, increasing both design and installation complexity.

IV. Dual Boost from Market Positioning and Brand Premium

From the demand perspective, core clients are concentrated in high-end catering and similar sectors. These customers demand exceptional quality, safety, and aesthetic appeal from display cabinets, exhibiting low price sensitivity. Take luxury retail outlets as an example: the cabinets must accentuate the premium positioning of the food offerings and align perfectly with the brand image. Consequently, retailers are willing to pay premium prices for such display units, with individual units priced at over $2000 – more than ten times the cost of standard glass cabinets.

The brand premium commanded by specialist manufacturers is also significant. Given the long-term technical expertise required for production, leading manufacturers often hold multiple patented technologies (such as seamless joining techniques and constant temperature/humidity control systems) alongside robust quality control frameworks. Their products undergo rigorous testing (including load-bearing, impact resistance, and airtightness assessments), achieving pass rates exceeding 98%, whereas small workshops yield rates of merely 60-70%. Consequently, branded manufacturers' products typically command a 50-80% premium over workshop-made alternatives, yet customers are willing to pay for this reliability.

After-sales costs also constitute part of the pricing structure, requiring professional teams for operation. Particularly for large all-glass display cabinets, crane equipment is necessary, and installation demands extremely high precision (horizontal error must be less than 2mm). A single installation can cost between $140-$420, with long-term warranty services provided (typically 2-5 years).

The premium price of all-glass display cabinets stems not solely from the ‘glass’ material itself, but rather reflects the combined value of materials, craftsmanship, functionality, and service. Serving as both a vessel for showcasing items and a carrier of brand image, while also acting as a protective barrier for cultural artefacts, every cost investment corresponds to tangible value. Ultra-clear glass enhances the refinement of displayed objects through superior light transmission, seamless construction elevates spatial aesthetics, and climate-controlled systems safeguard artefact security. For clients prioritising quality and experience, the premium price of all-glass display cabinets fundamentally represents a precise response to high-end demands and an acknowledgement of the product's intrinsic value.

Most popular More «

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?

-

Ideal temperature and temperature control points of cake cabinet

-

Which Cooluma compact commercial cake display cabinet is the best?

-

What are the procedures required for the certification of food display cabinets?

-

Aims to be a global supplier of commercial cold chain equipment, Cooluma