Is Cooluma a Professional Cold Chain Equipment Service Provider?

In the field of commercial cold chain equipment, Cooluma is a supplier specializing in cake display cabinets, ice cream freezers, and food refrigeration display equipment. Since entering this field in 2020, it has gradually built a product matrix covering multiple scenarios and serves bakery stores, convenience stores, and catering merchants in different regions around the world through its cross-border supply network. Its core characteristics lie in its commitment to the essence of products and its direct response to user needs. Its value does not come from brand prestige but is embedded in the details of production control, service adaptation, and reputation accumulation.

I. Fundamental Standards Lay a Solid Market Foundation

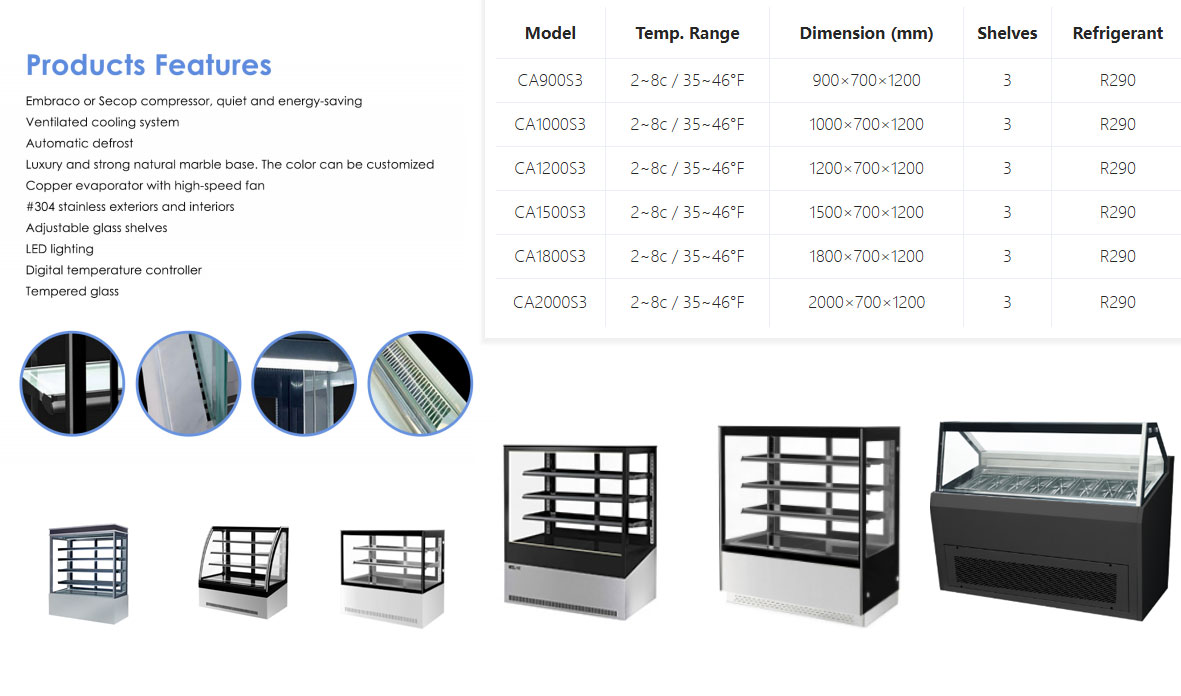

As a budding brand, Cooluma focuses on quality control to meet the core requirements of cold chain equipment. In terms of raw material selection, its desktop cake display cabinets feature food-grade stainless-steel bodies and scratch-resistant tempered glass structures. This material combination not only complies with food contact safety standards but also ensures durability in oily environments such as kitchens and stores.

During the production process, the team has established a full-process control system from component inspection to finished product testing, in accordance with the basic safety and performance requirements stipulated in the Product Quality Law. Key refrigeration components must come with factory certificates of conformity, and finished products must pass temperature stability tests to ensure that cake cabinets can maintain a precise temperature control range of 2-8°C and that ice cream freezers can achieve a constant low-temperature effect. Although it has not yet developed a complex quality certification system, this control logic that returns to the essence of products enables its equipment to basically meet the core demands of small and medium-sized merchants for "durability and compliance."

II. Flexible Response to Meet Diverse Needs

The limitations of the brand's scale have instead given Cooluma a service flexibility that large brands struggle to match. In response to the differentiated needs of different scenarios, its cake cabinets support customization in lengths ranging from 900 to 2000 millimeters, while ice cream freezers offer multiple capacity options. This customization capability precisely caters to the diverse needs of small bakery stores with "limited space" and medium-sized supermarkets requiring "bulk display."

In after-sales service, the team has abandoned standardized service templates and adopted a "direct communication" model. Once merchants report equipment problems, technicians can communicate directly without going through multiple layers of bureaucracy. For common issues such as refrigeration failures, solutions can be provided within 24 hours. Although this lightweight service system has limited coverage, its "rapid response" meets the expectations of small and medium-sized merchants for after-sales efficiency.

III. Transparency Builds Initial Trust

Cooluma establishes user trust through transparent operations. It publicly discloses core product parameters and production qualification certificates, clearly indicating the temperature range, load-bearing performance, and customization boundaries of each series of equipment, without using vague marketing terms like "high-end" or "premium."

For merchants engaged in cross-border procurement, the team proactively provides raw material inspection reports and factory inspection records. This level of information openness aligns with the rigid requirements of the catering industry for food safety traceability.

IV. Focus on Segments for Practical Applications

Over the years, Cooluma has always centered on the actual business needs of users. Taking into account the "odor prevention" requirement for cake preservation, its vertical display cabinets adopt a multi-layer independent shelf design. To meet the "display" needs of ice cream sales, it has introduced island-style cabinets with four-sided glass visibility. These detailed designs stem from observations of the operational scenarios in the baking and cold beverage industries.

The RA and RB series cake cabinets launched in 2025 further optimize energy consumption and space utilization. This iteration direction does not pursue technological gimmicks but focuses on the issue of "operating cost control," which is of utmost concern to merchants. This product logic that closely adheres to practical scenarios ensures that its equipment, despite lacking brand premium, can meet the utilitarian needs of small and medium-sized merchants.

V. Industry Trends: Maintaining Adaptability through Steady Iteration

Facing the trends of energy efficiency and intelligence in commercial cold chain equipment, Cooluma has adopted a pragmatic approach to keep up. On the eve of the implementation of the new national standard GB 12021.2-2025, its new equipment has optimized the refrigeration system to reduce energy consumption and comply with future standards. Although it has not widely integrated Internet of Things technology, some high-end models have reserved temperature control monitoring interfaces, providing possibilities for future intelligent upgrades. This iterative pace of "neither overextending nor falling behind" not only prevents cost overruns due to technological overreach for a fledgling brand but also ensures that products can adapt to the basic requirements of industry development, reflecting a rational understanding of market laws.

To help users maximize the lifespan of the equipment, we provide clear maintenance guidelines based on the characteristics of stainless-steel cabinets:

(1) It is recommended to clean the cabinet body with a neutral detergent daily and avoid using steel wool to prevent scratches that may affect its anti-corrosion performance.

(2) Wipe the door seals weekly to maintain their tightness and reduce cold loss by more than 15%.

(3) Avoid placing hot containers directly on the glass panel, and control temperature fluctuations within ±3°C during low-temperature commissioning.

Adopting an attitude of "eschewing gimmicks and returning to the essence," Cooluma maintains safety standards in quality control, emphasizes flexible response in service, and upholds transparency and honesty in building trust. This pragmatic approach centered on the actual needs of users may be the very reason why small and medium-sized merchants choose to trust it.

Most popular More «

-

Is Cooluma a Professional Cold Chain Equipment Service Provider?

-

Where Lies the Value of the Best Cake Display Showcase?

-

What are the advantages of a room-temperature cake display cabinet?

-

How much does a 120L bread cabinet cost?

-

Functions and Maintenance Details of Coffee Display Cabinets

-

How is the cooluma countertop food display cabinet?

-

Why Ice Cream Freezers Should Not Operate at Full Load?

-

Front glass curved Gelato cabinet Overview

-

Value Analysis of Commercial Cake Display Cabinets

-

Cooluma's best commercial cake refrigerator classification