Functions and Maintenance Details of Coffee Display Cabinets

In Europe and America, coffee is a trendy beverage. To address storage and display issues, various types of coffee display cabinets have entered the market. They serve as crucial carriers for shaping store images and attracting customers. In particular, the arc - shaped design with white cabinets and transparent glass panels not only meets the aesthetic needs of modern stores but also maximizes practical functions.

I. Core Functions of Coffee Display Cabinets

(I) Precise Refrigeration and Preservation to Ensure Coffee Quality

Through a stable low - temperature environment, the deterioration rate of coffee - related products is slowed down, preserving their flavor and taste. High - quality coffee display cabinets usually have the dual - temperature zone control capability. The temperature of the refrigerating chamber can be precisely controlled between 2 - 8°C, which can meet the storage requirements of dairy products such as fresh milk, whipped cream, and cheese (to prevent the growth of bacteria), and can also store freshly ground coffee powder (to slow down the oxidation rate and retain aroma substances). Some high - end models are also equipped with a micro - freezing zone of 0 - 2°C, which can store pre - chilled cold - brew coffee and cold - drip coffee for a short time, avoiding the dilution of concentration caused by ice melting.

At the same time, the humidity adjustment systeminside the display cabinet is of great importance. Coffee beans and coffee powder are extremely sensitive to humidity. Excessive humidity can easily cause moisture absorption, caking, and mold growth, while too low humidity will lead to the rapid volatilization of flavor substances. A qualified display cabinet will maintain the internal humidity within the appropriate range of 50% - 60%. Some models are also equipped with a humidity visualization display, which is convenient for operators to monitor in real - time and avoid affecting coffee quality due to fluctuations in environmental humidity.

(II) Optimize Display Effects and Enhance Consumption Appeal

As the "visual window" of coffee shops, coffee display cabinets can directly influence customers' purchasing decisions. The arc - shaped glass panel design not only weakens the bulky appearance of the cabinet but also expands the display field of view through curved surface refraction, allowing customers to clearly see the products displayed inside from multiple angles. With the LED cold light illumination systeminside the cabinet, the light is soft and does not release heat (to avoid local temperature rise affecting the refrigeration effect), which can highlight the color of coffee beans (such as the light brown transparency of lightly roasted beans and the shiny dark brown of darkly roasted beans), the layers of finished coffee (such as the creamy foam of lattes and the clear transparency of Americanos), and even create a "coffee luster" through the design of the light angle, stimulating customers' desire to buy.

In addition, the layered display structureis flexibly adjustable. The height of the partition can be adjusted according to the type of food: place bottled cold - brew coffee and canned coffee beans on the bottom layer (due to their heavier weight, to avoid excessive load on the upper layer), display finished freshly made coffee (such as cup - filled iced coffee) on the middle layer, and place small - portion coffee bean samples or cultural and creative products (such as coffee spoons and filter papers) on the upper layer. This not only ensures an orderly display but also provides convenient and flexible use.

(III) Additional Functions Adapted to Coffee Shop Scenarios

To adapt to various high - frequency usage scenarios, modern coffee display cabinets also have a number of practical additional functions:

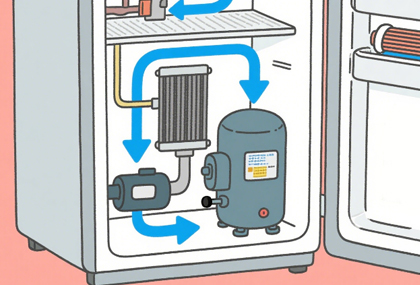

The quiet operation designuses a low - noise motor for the cabinet compressor, with the operating noise controlled below 40 decibels, avoiding equipment noise from interfering with customers' conversation experience, which is in line with the "quiet and comfortable" atmosphere requirements of coffee shops;

The energy - saving and consumption - reducing featuresreduce power consumption through designs such as double - layer insulating glass (to reduce heat conduction), variable - frequency compressors (which automatically adjust the operating power according to the internal temperature), and magnetic door seals (to prevent cold air leakage). Long - term use can reduce the operating costs of coffee shops; The intelligent monitoring function: Some models are equipped with a mobile phone APP connection function, which can display the internal temperature and humidity in real - time. If there is a temperature anomaly (such as a temperature rise caused by a compressor failure), it will automatically send an alarm message to the manager's mobile phone, preventing product deterioration due to equipment failures.

II. Maintenance Details of Display Cabinets

The maintenance of coffee display cabinets directly affects the equipment's lifespan and usage effect. If not properly maintained, problems such as reduced refrigeration efficiency, fogging of glass, and rusting of the cabinet may occur, which will affect coffee quality. Maintenance should be carried out from three aspects: daily maintenance, regular in - depth maintenance, and handling of special situations to establish a complete maintenance system.

(I) Daily Maintenance (Daily Operations)

1.Cleaning of Glass Panels: Glass is the "face" of the display cabinet. If stained with fingerprints or coffee stains, it will affect the display effect. After closing the store every day, wipe the glass with neutral cleaning agents (such as diluted dish soap) and a soft cloth. Avoid using acidic or alkaline cleaning agents (such as white vinegar, alcohol) to prevent corrosion of the glass coating; when wiping, move in the same direction to avoid scratches caused by back - and - forth friction; if the glass fogs up, check whether the door seal strip is aging (loose sealing can cause fogging due to the temperature difference between the inside and outside), and immediately dry the dust in the gaps of the seal strip with a dry cloth.

2.Maintenance of the Cabinet Surface: White cabinets are prone to showing dirt. Wipe the surface of the cabinet with a dry cloth every day to remove floating dust. If coffee is spilled, wipe it dry immediately with a damp cloth to prevent the pigment in the coffee liquid from staining the cabinet and causing yellowing; dust easily accumulates at the corners of the cabinet (especially at the curved transition areas). You can use a soft brush (such as a toothbrush) to clean the gaps to prevent dust accumulation from affecting the appearance.

3.Internal Cleaning and Inspection: Empty the remaining products in the display cabinet every day and wipe the internal partitions and trays with a dry cloth. If there are residues of dairy products (such as cream drips), wipe them with warm water and a neutral cleaning agent, and then dry them with a dry cloth (to avoid water residue causing rust on the partitions); at the same time, check whether the internal temperature display is normal. If the temperature fluctuates by more than ±1°C, contact a maintenance technician in a timely manner for inspection (it may be a thermostat failure).

(II) Regular In - depth Maintenance (Weekly/Monthly/Annual)

1.Weekly: Cleaning of Seal Strips and Heat Dissipation Vents: The seal strip is a key component to prevent cold air leakage. Wipe the surface of the seal strip with a damp cloth every week, and then apply talcum powder (or petroleum jelly) to the inner side of the seal strip to maintain its elasticity (to avoid aging and hardening); heat dissipation vents (usually located on the back of the cabinet) are prone to dust accumulation. Use a vacuum cleaner (with a brush attachment) to clean the dust in the heat dissipation vents every week. Excessive dust can cause poor heat dissipation of the compressor, reduce refrigeration efficiency, and even shorten the lifespan of the compressor.

2.Monthly: Inspection of Internal Components and Pipes: Remove the internal partitions and trays every month and wash them with warm water (avoid using hard brushes), and reinstall them after drying (to prevent bacteria growth due to water residue); at the same time, check whether there is any condensed water residue on the refrigeration pipes on the back of the cabinet (normally, the pipes should be dry. If there is a large amount of condensed water, it may be due to damage to the pipe insulation layer). If there are water droplets, dry them with a dry cloth and contact a maintenance technician to repair the insulation layer; in addition, check whether the partition brackets are loose. If there is any shaking, tighten the screws in a timely manner (to prevent the partitions from falling and damaging the products).

3.Annual: Professional Inspection and System Maintenance: Contact the equipment manufacturer or professional maintenance technicians for a comprehensive inspection every year, including: checking the operating status of the compressor (measuring the operating current to determine if it is normal), cleaning the condenser and evaporator (removing scale on the inner wall of the pipes to improve refrigeration efficiency), replacing the filter (if the equipment is equipped with an air filter, it should be replaced once a year to prevent dust from entering the refrigeration system), and calibrating the thermostat (to ensure that the temperature display is consistent with the actual temperature).

(III) Handling of Special Situations

1.Emergency Response to Power Outages: In case of a sudden power outage in the store, immediately close the display cabinet door to reduce cold air loss; if the power outage lasts for more than 2 hours, transfer perishable products such as dairy products and freshly ground coffee powder to a backup refrigerator to avoid product waste; after power is restored, wait for the temperature of the display cabinet to drop to the set range (usually 1 - 2 hours) before putting the products back in to avoid product deterioration caused by hot - cold alternation.

2.Emergency Response to Malfunctions: In case of malfunctions such as "refrigeration failure", "excessive noise", or "black - screen of the display", stop using the display cabinet immediately, unplug the power supply, and contact professional maintenance technicians. Do not disassemble it by yourself (especially core components such as the compressor and refrigeration pipes. Improper disassembly may lead to refrigerant leakage, environmental pollution, and safety hazards); after the malfunction is repaired, let the machine run empty for 2 hours. After confirming that the temperature and humidity are stable, put the coffee - related products back in.

III. Maintenance Precautions

1.Avoid placing the display cabinet in direct sunlight (sunlight will cause the cabinet temperature to rise and increase the load on the compressor), and do not place it near heat sources (such as coffee machines, ovens). It is recommended to keep a distance of more than 1 meter from heat sources;

2.Do not place heavy objects (such as coffee machines, storage boxes) on the top of the cabinet to avoid deformation of the cabinet and affecting the sealing effect of the door;

3.Open and close the door gently to avoid hitting the door hard, which may damage the seal strip or break the glass;

4.Do not fill the cabinet with products beyond 80% of its capacity. Leave a certain space (at least 10 cm) to ensure the circulation of cold air and avoid local overheating.

In conclusion, only by fully understanding its functional characteristics and establishing a scientific maintenance system can the lifespan of coffee display cabinets be extended, coffee quality be guaranteed, and a good visual image and operating environment be created.

Most popular More «

-

What is the price of a cake display cabinet in Mumbai?

-

Review of Pastry Countertop Display Cabinet T90C/T90S

-

What techniques are crucial for quality in glass cabinet manufacturing?

-

What are the models available for the Cooluma bread refrigerator with two shelves?

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator