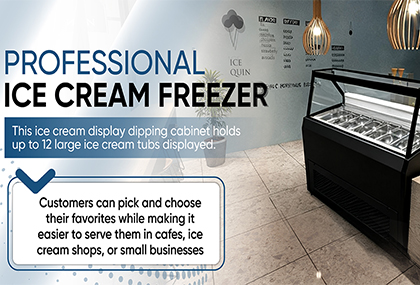

Front glass curved Gelato cabinet Overview

There are thousands of forms of Gelato display cabinets in the market, and different appearance designs are protected by exclusive patents. They are designed after strict market research, data analysis, performance prediction and evaluation. QW series display cabinets are one of the professional designs of cooluma. Let me introduce you to the details below.

From the appearance, it adopts the layout of round on top and square on bottom, with a large footprint at the bottom, which can be placed stably anywhere. The upper part adopts circular glass design to bring good visual experience. Two single sliding doors reduce the loss of cold air, and a honeycomb heat dissipation panel is located near the middle of the front.

The advantages of capacity are more obvious. The single cabinet capacity ranges from 255L to 735L, and the minimum can make 8 kinds of Gelato, and the maximum can make 24 kinds of Gelato. It is sufficient for most scenarios. If you want to pursue more kinds of Gelato, it is necessary to choose multiple display cabinets, because the volume of a single cabinet is too large, which is not conducive to placement and transportation.

| Model | Pans | Dimension (mm) | Capacity (L) | Temperature |

| QW8 | 8 | 842*1126*1267 | 255 | -18~-22 |

| QW10 | 10 | 1012*1126*1267 | 315 | -18~-22 |

| QW12 | 12 | 1182*1126*1267 | 375 | -18~-22 |

| QW14 | 14 | 1352*1126*1267 | 435 | -18~-22 |

| QW16 | 16 | 1522*1126*1267 | 495 | -18~-22 |

| QW18 | 18 | 1692*1126*1267 | 555 | -18~-22 |

| QW20 | 20 | 1862*1126*1267 | 615 | -18~-22 |

| QW22 | 22 | 2032*1126*1267 | 675 | -18~-22 |

| QW24 | 24 | 2202*1126*1267 | 735 | -18~-22 |

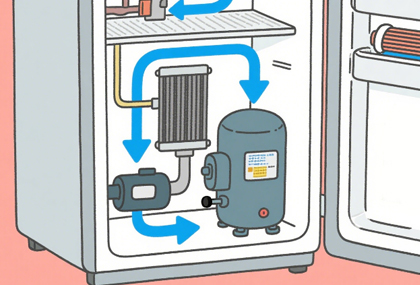

In terms of internal performance, high-capacity compressors deliver superior cooling efficiency, enabling faster temperature regulation in target spaces and reduced waiting times. Low-capacity compressors often experience performance degradation due to insufficient load capacity, whereas high-capacity models maintain stable cooling output through enhanced compression capabilities. Additionally, in large-space/high-load scenarios, high-capacity compressors can rapidly reach set temperatures and enter low-frequency standby mode, while low-capacity models may require continuous full-load operation to barely maintain temperature, resulting in higher long-term energy consumption.

In the field of safety, Gelato cabinets adopt certifications compliant with various national safety qualifications, such as China's 3C certification, the EU's CE certification, the US UL certification, and Japan's PSE certification. These are core requirements to ensure equipment compliance and operational safety. Essentially, they aim to mitigate risks throughout the entire lifecycle—from design and production to usage—by meeting the mandatory safety standards for refrigeration equipment in different countries/regions.

Gelato has very high requirements on temperature and texture preservation, and the core 8 points of attention for its special cabinet are as follows:

1. Precise temperature control

It needs to be maintained at-12℃to-8℃(different from the-18℃below ordinary ice cream), too high temperature is easy to melt and stratify, too low will lead to Gelato hardening and loss of dense taste, so the temperature of the cabinet thermometer needs to be calibrated regularly.

2. Avoid frequent door opening and closing

Every time the door is opened, the outside hot air will enter, resulting in temperature fluctuations inside the cabinet, which may cause Gelato surface melting and then ice formation (formation of ice crystals), affecting the taste. It is recommended to take a quick operation when using, reducing the time and frequency of opening the door.

3. Store in separate areas to avoid flavoring

If there are multiple flavors of Gelato in the cabinet, special containers or plastic wrap should be used to separate them to prevent different flavors from permeating each other (such as nut and fruit flavors are easy to taste), and avoid direct contact with metal parts in the cabinet to cause adhesion.

4. Clean the cabinet regularly

Clean at least once a week by wiping the inner wall, partition and meal taking tools with a neutral cleaner (avoid acid/alkaline corrosion) to prevent bacteria breeding from residual Gelato residue. After cleaning, dry it before restarting to avoid water condensation affecting refrigeration.

5. Control of inventory levels to avoid overstocking

The storage capacity of Gelato in the cabinet should not exceed 80% of the total volume, and enough space should be reserved for cold air circulation. If the pile is too full, the local temperature may be uneven, resulting in deterioration or poor taste of some Gelato.

6. Special and clean dining utensils

Clean the tools immediately after each use to prevent bacteria from being brought in; avoid scratching the bottom of the cabinet when digging to prevent damage to the inner tank or carrying out impurities.

7. Concern for environmental humidity

The ambient humidity around Gelato cabinet should be controlled at 40%~60%. Excessive humidity is easy to cause condensation outside the cabinet and mold growth inside the cabinet, while too low humidity may cause moisture loss of Gelato and dry taste. It can be adjusted with dehumidification or humidification equipment.

8. Periodic inspection of refrigeration system

Check whether the evaporator and condenser in the cabinet are dusted every month. If too much dust affects the refrigeration efficiency, clean it with a soft brush. At the same time, observe whether the refrigeration is stable (whether there is abnormal noise or sudden temperature rise). Stop the machine for maintenance in time if problems are found to avoid batch deterioration of Gelato.

Most popular More «

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?

-

Ideal temperature and temperature control points of cake cabinet

-

Which Cooluma compact commercial cake display cabinet is the best?