How to solve the core pain points countertop display cases of bakery stores?

For bakeries, the temperature inside the oven determines the texture of the bread, while the display case determines the “vitality” of the products—it serves as both the ‘stage’ for baked goods and the bridge connecting products to customers. Cooluma has been deeply rooted in the commercial baking equipment sector for years, focusing on “solving practical operational pain points.”

Ignite Customer Desire with Transparent Display

“Why does freshly baked bread look golden and tempting when it comes out of the oven, yet appear dull and lifeless once placed in the counter display case?” This is a common frustration shared by many bakery owners. Approximately 80% of customers' impulse to purchase baked goods stems from visual appeal. A blurry display directly diminishes product attractiveness.

The Cooluma series display cabinets feature ultra-clear tempered glass for 360° transparency, with over 92% light transmittance and zero visual blind spots. This allows customers to clearly see the flaky layers of croissants and the wheat bran grains in toast. Compared to standard glass, its anti-reflective coating effectively prevents glare from direct lighting, ensuring products remain fully visible even under intense in-store lighting.

Thoughtfully designed with an embedded LED cool-light system, the display maintains a warm white light temperature between 3000K-4000K. This avoids the cold, clinical appearance of cool white light while preventing color distortion common in warmer tones. Light is evenly distributed along the cabinet top and inner shelves, softly enveloping each product. This enhances the glossy caramel hue of Danish pastries and accentuates the delicate creaminess of buttercream cakes.

Solving the Challenge of Baking Product Freshness

“Cream cakes collapse after half a day, and improperly chilled mousses develop watery textures.” The freshness of baked goods directly impacts a store's loss rate. Data shows that temperature inaccuracies can cause 15%-20% loss in baked goods—a significant cost burden for bakeries operating on slim profit margins.

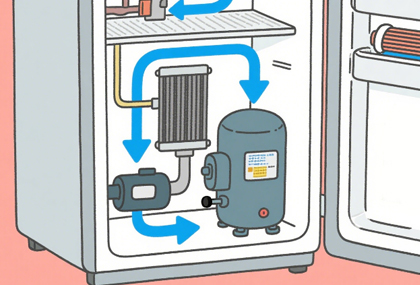

An effective solution is an independent dual-cycle refrigeration system, enabling separate temperature control for upper and lower sections. The upper section can be set to 0-5°C for storing temperature-sensitive items like cream cakes and mousses, while the lower section operates at 5-10°C for temperature-sensitive items like Danish pastries and cream puffs. This prevents flavor transfer between products and spoilage due to improper temperatures.

At the core refrigeration level, the use of inverter compressors keeps temperature fluctuations within ±0.5°C, effectively maintaining the stable texture of cream and the soft, fluffy mouthfeel of cakes. Simultaneously, the cabinet features intelligent humidity control, maintaining internal humidity within the optimal range of 65%-75%. This prevents bread from drying out and hardening while also avoiding frost formation on mousse surfaces.

Naturally, the cabinet also features an abnormal temperature alarm. Should temperatures exceed the set range, audible and visual alerts prompt staff to address the issue promptly, preventing batch losses due to equipment malfunctions.

The “Invisible” Display Solution for Small Outlets

For neighborhood bakeries, countertop display cases must showcase ample product variety without making the store feel cluttered. Featuring an ultra-slim 32cm-thick design, they can be seamlessly integrated into countertops or wall-mounted spaces, eliminating the need for additional floor area. This allows even 10㎡ shops to achieve a layout combining diverse product display with spacious work areas:

(1) Optimized structural design maximizes height, depth, and storage capacity

(2) Customized craftsmanship—beyond screen printing and laser engraving—enhances textural richness.

Within limited space, adjustable shelving maximizes utilization. Shelf heights freely adjust, stacking up to 3 layers of cupcakes or 2 layers of toast, increasing total display capacity by 40%.

Additionally, concealed storage drawers beneath the cabinet hold disposable gloves, takeout containers, and other supplies, achieving dual “display + storage” functionality.

Reducing Labor Costs Through Detailed Design

Bakeries often face staffing shortages during peak hours. Staff must handle cashier duties, packaging, restocking, and cleaning display cases simultaneously. Complex operations hinder service efficiency, necessitating “human-centered operation” design principles. The entire series features removable shelves and magnetic glass doors.

Shelves are crafted from food-grade 304 stainless steel and can be easily removed with a simple pull. Cleaning requires no cabinet relocation—simply rinse directly, reducing cleaning time by 60% compared to standard display cabinets.

Magnetic glass doors eliminate hinge installation, ensuring smooth operation and superior sealing. Staff can replenish inventory with a simple push, requiring only one hand—avoiding the operational hassles caused by hinge jams in conventional doors.

Additionally, integrated functions like temperature regulation, lighting control, and timed defrosting feature an intuitive interface. New staff can master operation after just 5 minutes of training. This reduces daily cleaning and restocking time by 1.5 hours. “What once required three people during peak hours can now be easily handled by two.”

Note: The focus lies in reducing costs, enhancing operational efficiency, and lowering labor expenses.

Long-Term Operational Cost Optimization Keys

Commercial display cabinets operate 24/7, making electricity consumption a significant ongoing cost for bakeries. Due to their excellent insulation and efficient compressor operation, monthly electricity bills often reach hundreds of dollars. This necessitates solutions certified with National Class 1 Energy Efficiency, utilizing vacuum double-layer Low-E glass—which offers three times better insulation than standard glass, effectively reducing cold air loss. Paired with variable-frequency compressors that automatically reduce speed after reaching set temperatures, this saves 30%-40% in costs.

Take Cooluma's RA Series countertop bread display cabinet as an example: core components come with a 5-year warranty, compressors with a 10-year guarantee, and its product failure rate is below 0.5%—far lower than the industry average of 3%. This prevents business interruption losses due to equipment repairs. “It seemed a bit pricier than standard cabinets at purchase, but factoring in electricity and maintenance costs, it pays for itself within a year,” a common sentiment among long-term Cooluma users.

Comprehensive Coverage from Fresh-Baked to Customized

Different bakery types have distinct display needs: Fresh-baked bakeries require temperature-controlled showcases, premium cake shops require high-end refrigerated displays, while multi-concept bakeries need versatile solutions for diverse product categories. Beyond core refrigeration and countertop series, Cooluma has developed the RA-T Series Fresh-Baked Display Cabinet. Utilizing hot-air circulation heating technology, it maintains temperatures between 38-45°C to preserve the warmth and wheat aroma of freshly baked goods—ideal for showcasing breakfast items.

For high-end custom cake shops, personalized display cabinet customization services allow tailoring cabinet colors and materials to match store decor, even printing brand logos on glass to integrate seamlessly into the shop's design.

Competition in the baking industry has long extended beyond “product taste” to encompass “consumer experience,” whose importance is self-evident. By delving into the operational realities of bakeries, we address every pain point across multiple dimensions: the customer's visual experience, the owner's cost control, and the staff's operational efficiency.

For bakery owners, technological innovation and user-centric design demonstrate that quality display cabinets not only preserve baked goods at their peak condition but also elevate store aesthetics and reduce operational costs—proving that “details determine success.”

Most popular More «

-

How to solve the core pain points countertop display cases of bakery stores?

-

What is the price of a cake display cabinet in Mumbai?

-

Review of Pastry Countertop Display Cabinet T90C/T90S

-

What techniques are crucial for quality in glass cabinet manufacturing?

-

What are the models available for the Cooluma bread refrigerator with two shelves?

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy