What techniques are crucial for quality in glass cabinet manufacturing?

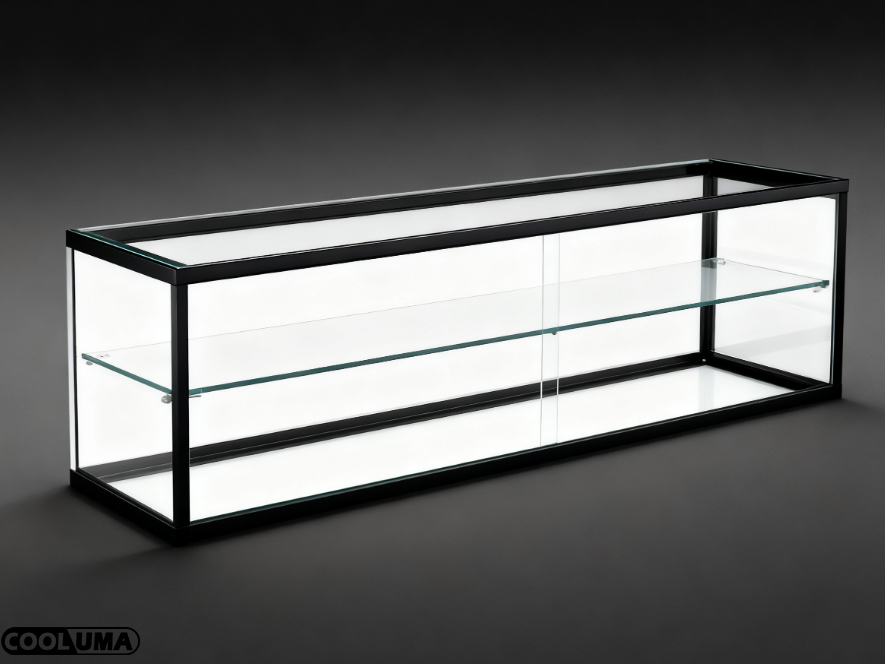

Glass display cabinets see widespread application in everyday commercial settings, serving to store and showcase items such as cakes, bread, and delicacies. Many assume these cabinets are merely simple combinations of ‘glass and frames’ – until a customer arrives with a cracked display unit, revealing the truth: while some glass cabinets remain perfectly flat and crystal-clear after five years, others develop warped doors and fogged glass within just three months. The root cause lies entirely in the ‘invisible technical details’.

Having spent three years in the United States working in technical roles for glass furniture contract manufacturers, handling everything from domestic wine cabinets to retail display units, I shall now break down the core technologies behind glass cabinet production. Whether you're seeking factory customisation or entering the industry as a novice, this guide will help you avoid common pitfalls.

I. Fundamental Material Pre-treatment: The ‘Inherent Properties’ of Glass and Frames

Eighty percent of a glass cabinet's durability is determined during material processing. Simply purchasing tempered glass is insufficient; each step requires adherence to technical standards.

1. Glass Processing: Tempering, Cutting, and Edge Polishing – None Can Be Omitted

Glass serves as both the cabinet's ‘face’ and its safety core. These three technical processes directly dictate longevity:

- Tempering: Mandatory compliance with ‘3C Standard’ requirements For both domestic and commercial glass cabinets, tempering is compulsory (except for specially crafted art glass), as mandated by national standards. Reputable manufacturers employ the ‘physical tempering method’—heating ordinary glass to 600-700°C before rapid cooling with cold air, creating surface compressive stress. Glass treated this way boasts 3-5 times the impact resistance of ordinary glass. Even if shattered, it breaks into rounded particles without sharp edges, preventing cuts. We've witnessed small workshops passing off ordinary glass as tempered glass; customers cleaning it caused it to crack instantly, nearly resulting in a safety incident.

- Precision cutting: tolerances must be within 0.1mm for acceptance. Inaccurate glass dimensions cause gaps during assembly or lead to compression fractures. Modern factories now employ CNC cutting machines, achieving tenfold greater precision than traditional manual cutting. For instance, when producing a 1.2-metre-long side panel for a wine cabinet, CNC cutting maintains tolerances within 0.1mm, whereas manual cutting often yields 2-3mm deviations, preventing doors from closing properly. Additionally, non-standard glass (such as curved display cases) requires modelling followed by laser cutting, alongside specialised moulds for stabilisation during heating and shaping to prevent distortion.

- Edge Grinding and Chamfering: Dual Assurance of Tactile Comfort and Safety Glass edges are its most vulnerable points, necessitating edge grinding. Factories commonly employ diamond edge grinders, executing three stages: coarse grinding, fine grinding, and polishing. The resulting edges feel smooth to the touch and pose no risk of cuts. Countertop glass further requires a 45° chamfer, enhancing aesthetics while reducing the risk of breakage from impacts. One client commissioned a bespoke cosmetics display cabinet where the factory omitted the fine grinding step. An employee sustained a wrist injury from the rough glass edge while handling goods, resulting in compensation for medical expenses and rework.

2. Frame Fabrication: The ‘Stability Technology’ of Metal and Wood

The frame serves as the ‘skeleton’ of a glass cabinet, with distinct fabrication techniques for different materials. Common options include aluminium alloy, stainless steel, and solid wood:

- Aluminium alloy frames: Anodising is key to corrosion resistance. Lightweight and economical, aluminium is the preferred choice for domestic glass cabinets. However, it oxidises and darkens easily. Reputable manufacturers apply anodising—immersing the alloy in an electrolyte solution and applying an electric current to form an oxide layer. This not only prevents corrosion but also allows for colouring (e.g., black, champagne). For outdoor glass cabinets, an additional ‘electrophoretic coating’ is applied, enhancing weather resistance to withstand three years of direct sunlight without discolouration. Small workshops often use brushed aluminium alloy without oxidation treatment, which begins to blacken and flake within six months.

- Stainless steel frames: Welding and polishing determine aesthetics Stainless steel frames suit commercial applications (e.g., supermarket refrigeration units), with core techniques lying in welding and polishing. Modern ‘pulse argon arc welding’ produces fine, smooth weld points without slag. Post-welding, ‘mirror polishing machines’ integrate welds seamlessly into the frame, creating a seamless appearance. For 304 stainless steel, ‘passivation treatment’ prevents rust when exposed to food or humid environments.

- Solid Wood Frames: Moisture Protection Trumps Joinery Solid wood frames offer superior texture but are susceptible to warping from damp. Manufacturers first subject timber to ‘vacuum drying treatment’, controlling moisture content to 8%-12% (or below 10% in humid southern regions). This is followed by ‘mortise and tenon joinery’, which provides greater stability than mere screw fastening. Surfaces receive at least three coats of water-based wood lacquer, which is environmentally friendly while sealing out moisture to prevent mould growth that could warp the cabinet.

II. Core Assembly Techniques: The Secret to Seamless Glass-Frame Integration

Many glass cabinets develop issues over time—whether cracked glass or warped doors—due to flawed assembly. This step demands meticulous craftsmanship and precision tools.

1. Glass Fixing: Dual Assurance Through Adhesives and Hardware

Glass must not be secured solely by screws (which can cause compression fractures). The current industry standard employs a dual approach: adhesive bonding combined with metal clips.

Adhesives must utilise ‘neutral silicone structural sealant,’ not standard glass sealant. Neutral sealant does not corrode glass or metal, offers superior bonding strength, and withstands extreme temperatures. Even in humid environments like kitchens or bathrooms, it maintains integrity for over a decade without failure. When applying sealant, first clean the glass and frame surfaces with alcohol. Then use a caulking gun to apply the sealant at a steady pace, maintaining a bead width of 3-5mm. Smooth the bead with a squeegee for an aesthetically pleasing finish and to ensure full adhesion.

Hardware clips are primarily used to connect glass shelves and side panels. Select ‘304 stainless steel clips’ paired with rubber washers. This combination secures the glass while absorbing vibrations, preventing cracks caused by uneven stress distribution. We've witnessed factories using plastic clips to cut costs, resulting in shelves collapsing and shattering when customers placed a few bottles of wine on them.

2. Door Assembly: Precision Control of Hinges and Rails

Glass cabinet doors present the most common issues, hinging on the installation technique of hinges (for hinged doors) and rails (for sliding doors):

- Hinged doors: Precise load-bearing and positioning Given the weight of glass cabinet doors, ‘heavy-duty hydraulic hinges’ are essential. Each hinge must support at least 15kg and feature ‘three-dimensional adjustment’—enabling fine-tuning front/back, left/right, and up/down to ensure uniform gaps between door and cabinet (tolerance ≤0.5mm). During installation, pre-drill holes in the frame with positioning tolerances within 1mm. Misaligned hinges cause door sagging, potentially leading to glass compression and cracking over time.

- Sliding cabinet doors: Parallel track alignment is paramount. Sticking or derailing doors result from non-parallel track installation. Manufacturers employ laser levelling instruments to ensure perfect parallelism between upper and lower tracks (parallelism tolerance ≤0.3mm/m). A 2-3mm clearance must be maintained between tracks to facilitate smooth door movement. Track-mounted buffers prevent glass breakage from impact during closure while reducing operational noise.

3. Sealing and Anti-Fog: Technical ‘Experience Enhancements’ in the Details

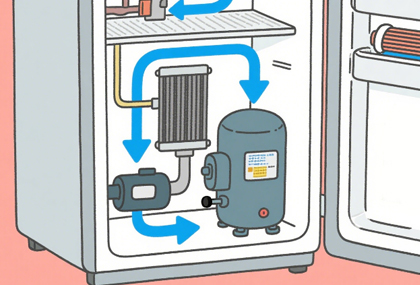

For glass cabinets requiring sealing or temperature control, such as wine cellars or refrigerators, two specialised techniques are added:

Sealing employs ‘EPDM sealing strips,’ which resist ageing better than standard rubber strips. These must fit tightly against the door frame and are tested with an ‘airtightness tester’ to ensure no air leakage—otherwise, the wine cellar's temperature stability would deteriorate, and the refrigerator would consume more electricity. Anti-fogging is achieved through either a ‘nano-anti-fog coating’ applied to the glass surface or the use of ‘insulated laminated glass’ (filled with inert gas). This prevents condensation caused by temperature differentials between the interior and exterior, which could obscure the display. Jewellery display cabinets in shopping centres typically employ this technology, ensuring the glass remains crystal clear even when air conditioning is in use.

III. Finished Product Inspection: Pre-shipment Quality Assurance Techniques

High-quality glass cabinets undergo three mandatory inspection rounds prior to dispatch, with omission of any round posing potential risks:

1. Safety Inspection: Impact resistance is tested using a ‘ball drop impact tester’, while frame load-bearing capacity is assessed with a ‘compression tester’ (e.g., shelves must withstand over five times their own weight). Compliance is verified against the national standard GB 15763.2-2005 ‘Safety Glass for Buildings - Part 2: Tempered Glass’.

2. Functional Testing: Hinged doors undergo 5,000 opening/closing cycles to verify hinge stability; sliding doors endure 10,000 operations to assess track smoothness; sealed cabinets undergo 24-hour constant-temperature testing to confirm temperature fluctuations remain within ±1°C.

3. Visual Inspection: Employ a ‘high-intensity inspection lamp’ to examine glass surfaces for scratches or bubbles. Use a ‘feeler gauge’ to verify uniform door panel gaps, ensuring flawless appearance.

When selecting glass cabinets, focus on these three technical points for certainty

Whether commissioning bespoke units or purchasing ready-made products, adhering to these three core technical criteria will help avoid 90% of pitfalls:

- Glass must bear the 3C certification mark, with smooth edges free of burrs. A crisp ring when tapped indicates quality (a dull sound suggests semi-tempered glass);

- Frame connections must be secure with no wobble or squeaks. For aluminium frames, check for uniform oxide coating; for solid wood frames, inspect for cracks or warping;

- Cabinet doors should open and close smoothly with uniform gaps. Test the seal by running your hand along the door-to-body joint – no draught should be felt.

The quality of a glass cabinet is never determined by ‘thick glass’ alone, but lies in the technical details of every processing step and assembly operation. For specific customisation requirements (e.g., dimensions, materials),

Most popular More «

-

What techniques are crucial for quality in glass cabinet manufacturing?

-

What are the models available for the Cooluma bread refrigerator with two shelves?

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?