Comprehensive Guide to Glass Display Cabinets: Usage and Scenario Applications

In the era dominated by visual consumption, glass display cabinets have evolved from simple "storage containers" to "brand visual carriers", becoming a core tool for retail, catering, cultural and creative industries to enhance product value. In recent years, with the deepening trend of "experiential consumption", the demand for glass display cabinets has shown three major characteristics: First, the demand for "transparency" has surged, with the application rate of ultra-clear glass and frameless designs increasing by 40% compared to 5 years ago. Consumers' preference for "unobstructed viewing" has driven equipment toward "invisible display"; second, "functional integration" has become mainstream, with over 70% of commercial glass cabinets now equipped with LED lighting, constant temperature control, smart locks and other modules. Especially in the catering industry, the penetration rate of glass cabinets with low-temperature preservation functions has exceeded 65%; third, the trend of "environmental protection and lightweight" is obvious. Equipment using ultra-thin tempered glass and aluminum alloy frames is 30% lighter than traditional models, with energy consumption reduced by 25%. Its importance is not only reflected in the basic function of "product protection" (dustproof, moistureproof, damage prevention), but also in magnifying product details through light and shadow matching and spatial hierarchy design to stimulate consumers' purchasing desire—data shows that stores equipped with professional glass display cabinets have an average 58% increase in product attention and a 23% increase in customer unit price, demonstrating its irreplaceability in commercial scenarios.

1. Comparison from Light Transmittance to Safety

Glass material is the core determinant of display effectiveness and usage safety. Performance differences between different types of glass directly affect applicable scenarios. The following analysis is conducted from key indicators combined with practical application needs:

| Glass Type | Light Transmittance | Impact Resistance (National Standard) | Temperature Resistance Range | Key Features | Suitable Scenarios |

|---|---|---|---|---|---|

| Ordinary Float Glass | 82%-85% | ≤50kJ/m² | -20℃-60℃ | Low cost, easy to process, surface prone to scratches | Room temperature storage (e.g., stationery, toys) |

| Tempered Glass | 80%-83% | ≥250kJ/m² | -40℃-280℃ | Breaks into granular pieces, strong impact resistance | High-frequency commercial use scenarios (retail, catering) |

| Ultra-Clear Glass | 91%-93% | ≥240kJ/m² | -40℃-300℃ | Low iron content, no greenish tint, excellent light transmittance | High-end jewelry, luxury goods, cultural and creative displays |

| Laminated Glass | 75%-80% | ≥300kJ/m² | -30℃-200℃ | PVB film interlayer, does not shatter when broken | High-altitude displays, near children's activity areas |

| Coated Glass | 60%-75% | ≥250kJ/m² | -30℃-250℃ | UV resistant (blocking rate ≥90%), reduces glare | Calligraphy and painting, specimens, photosensitive product displays |

Usage Points: Priority should be given to matching scenario requirements when selecting—for example, the catering industry (especially for Gelato and cake displays) needs to balance light transmittance and low-temperature resistance; ultra-clear tempered glass (temperature resistance -40℃-280℃, suitable for refrigeration functions) is recommended. The jewelry industry needs to highlight product luster, so ultra-clear glass with anti-glare coating is the best combination. Display cabinets near children's playgrounds must use laminated glass to avoid scratch risks after breakage.

2.Key Factors Affecting the Service Life of Glass Display Cabinets

The durability of glass display cabinets depends not only on the glass material but also on the cabinet frame, connection structure and load-bearing design. The following breaks down from three core dimensions:

Frame Material Selection

Aluminum Alloy Frame: Lightweight (density 2.7g/cm³, 60% lighter than steel), corrosion-resistant, surface can be anodized (scratch-resistant, easy to clean), suitable for high-frequency commercial use scenarios (e.g., supermarkets, dessert shops), service life up to 8-10 years;

Carbon Steel Frame: Strong load-bearing capacity (≥80kg per square meter), but prone to rust and requires electrostatic spraying, suitable for heavy product displays (e.g., home appliances, tools), service life 5-7 years;

Solid Wood Frame: Good texture, suitable for cultural and creative, intangible cultural heritage product displays, but requires moisture-proof treatment (e.g., waterproof paint coating) to avoid deformation in humid environments, service life 3-5 years.

Glass Connection Methods

UV glue bonding:Seamless adhesive bonding: Small gap

(≤0.5mm), visually "seamless integral", high aesthetics, but limited load-bearing (single glass load≤15kg), suitable for lightweight products (jewelry, accessories);

Metal Clip Fixing: Connected by stainless steel clips and screws, strong load-bearing (single glass load≤50kg), detachable for maintenance, but with larger gaps (1-2mm), requiring regular inspection of screw tightness;

Embedded Card Slot: Glass embedded into frame card slot, with sealing strips, excellent dust resistance (dustproof rate≥95%), suitable for dust-free display scenarios (e.g., electronic products, precision parts).

Load-Bearing Design Principles

The load-bearing capacity of the bottom shelf should be≥upper shelves (bottom recommended≥50kg/㎡, upper≥20kg/㎡) to avoid "top-heavy"; glass shelf thickness should match load-bearing—5mm tempered glass for load≤20kg, 8mm for 20-30kg, 10mm and above for over 30kg.

Precautions: Ensure the ground is level during installation (error≤2mm), otherwise uneven frame stress may cause glass cracking; inspect connection parts regularly (every 3 months), apply anti-rust oil to metal clips, and replace glass immediately if cracks appear at UV glue bonding joints.

3.How High-Transparency Glass Enhances Product Value

The core demand for display cabinets in the jewelry industry is to "highlight luster and emphasize details". The application of glass display cabinets should focus on "light and shadow matching + safety protection":

Display Effect Design:

Use three-layer ultra-clear tempered glass (92% light transmittance) to create a "fully transparent" cabinet, with 4000K warm white LED light strips (color rendering index Ra≥95, close to natural light) installed inside, illuminating from multiple angles (top and side). For diamond products, side lighting can highlight the cut reflections; for gold products, top lighting enhances the metallic luster. Avoid using cool white light (which tends to make jewelry appear "cold and hard", reducing texture).

Functional Configuration Points:

Equipped with anti-fingerprint glass (surface coated with AF anti-fingerprint film, reducing fingerprint residue by 80%) to prevent marks left by customer touch; add electronic smart locks (supporting password + NFC card swiping), and install shock-absorbing pads (5mm thick) at the bottom of the cabinet to reduce vibrations from pedestrian movement and prevent jewelry displacement.

Application Scenario Segmentation:

Window displays use "frameless ultra-clear glass cabinets" with external spotlights to attract passers-by; in-store counters adopt "semi-open glass cabinets" (front glass can be pushed and pulled) for easy access by staff while maintaining display integrity; high-end customization areas use "constant temperature and humidity glass cabinets" (temperature 22℃±2℃, humidity 50%±5%) to prevent organic jewelry such as pearls and coral from losing water and becoming brittle.

Precautions: Avoid direct sunlight (install UV blocking film to prevent jewelry fading); clean the glass with suede cloth daily, and do not use alcohol-containing cleaners (which may corrode the anti-fingerprint film).

4. How to Balance "Freshness Preservation" and "Display"

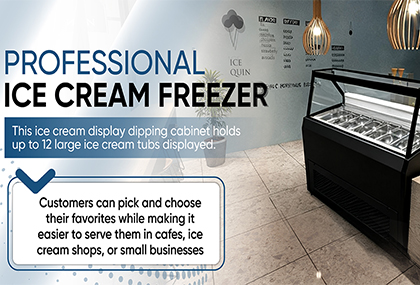

The catering industry (especially cold food, such as Gelato, cakes, sushi) requires glass display cabinets to provide "low-temperature preservation + visual appeal", focusing on glass temperature resistance and cabinet sealing:

Special Requirements for Gelato Glass Cabinets:

Glass should be ultra-clear tempered glass (temperature resistance -40℃-280℃, suitable for refrigeration environments of -12℃to -18℃). The cabinet uses "three-layer insulated glass" (filled with inert gas in the middle, improving thermal insulation by 40%) to prevent fogging caused by temperature differences between inside and outside the glass (inner wall should be equipped with electric heating wires, temperature 50℃±5℃, to eliminate condensation). The display shelf is designed with a 15°tilt, conforming to ergonomics, making it easy for customers to view flavor labels and preventing Gelato from overflowing due to tilting.

Core Configuration of Cake Display Cabinets:

Glass uses anti-fog tempered glass (surface coated with hydrophilic coating, fog dissipation speed≤3 seconds). Cabinet temperature is controlled at 2℃-8℃. The connection between glass and frame is sealed with food-grade silica gel (sealing degree≥98%, preventing cold air leakage). Internal LED lights use 3000K warm light to avoid direct strong light irradiation on cake cream (preventing melting or discoloration).

Usage Points:

Check glass sealing before daily business (after closing the cabinet door, test the gap with a paper strip; if the strip cannot be pulled, it is qualified); use neutral cleaner (such as diluted dish soap) for cleaning, avoid steel wool (which may scratch the glass); refrigerated glass cabinets need defrosting weekly (frost layer thickness≤5mm, otherwise refrigeration efficiency will be affected and energy consumption increased).

5.How to Balance "Protection" and "Experience"

Cultural and creative products, intangible cultural heritage items (such as handcrafted ceramics, ancient books, embroidery) often have "fragile, moisture-sensitive, light-sensitive" characteristics. Glass display cabinets need to balance "display visibility" and "product protection":

Material and Function Adaptation:

Use laminated ultra-clear glass (91% light transmittance, does not shatter when broken, protecting fragile products) with coated glass (UV blocking rate≥92%, preventing fading of ancient books and embroidery); install a constant temperature and humidity system inside the cabinet (temperature 18℃±2℃, humidity 55%±5%) to avoid ceramic cracking and thread mildew due to moisture.

Display Scenario Design:

Handcrafted ceramics: Lay anti-slip flannelette at the bottom of the glass cabinet, with spotlights irradiation from obliquely below to highlight ceramic textures and glazes;

Ancient rare books: Use "drawer-type glass cabinets" (glass is pull-out, no contact with ancient books when opened), place insect repellents (such as natural camphor wood strips) inside to avoid moth damage;

Embroidery products: Fix with transparent acrylic brackets, open "ventilation holes" on the side of the glass cabinet (with dust filters) to maintain air circulation without dust accumulation.

Precautions: Check constant temperature and humidity system parameters monthly; turn on dehumidification function when humidity exceeds 60%; clean glass by first removing gap dust with a soft brush, then wiping with a slightly damp cloth to avoid dust particles scratching the glass.

6.Application and Maintenance of Scratch-Resistant Glass Display Cabinets

Electronic product displays (such as mobile phones, headphones, smart watches) need to highlight "sense of technology" while avoiding glass scratches affecting appearance. The core points are as follows:

(1)Glass Material Selection

Use "ultra-clear tempered glass + scratch-resistant coating" (Mohs hardness≥7H, resistant to daily scratches from keys, coins, etc.). Some high-end display cabinets use "sapphire glass" (Mohs hardness 9H, close to diamond, reducing scratch marks by 95%), but the cost is higher, suitable for flagship model displays.

(2)Display Function Design

Install a "wireless charging module" inside the glass cabinet (mobile phones can be charged by placing them, avoiding messy wires), with 6500K cool white LED lights (color rendering index Ra≥90, restoring the metallic texture of electronic products); open "data interfaces" on the side of the cabinet for staff to connect devices and demonstrate functions, with silicone plugs sealing the interfaces (dustproof and waterproof).

(3)Usage and Maintenance Points

Clean the glass daily with a microfiber cloth (such as eyeglass cloth); for stubborn stains, use neutral cleaner diluted with water (ratio 1:10) for wiping; avoid placing the display cabinet near magnetic fields (such as speakers, generators) to prevent wireless charging module failure; if minor scratches appear on the glass, apply glass polish (such as cerium oxide polishing paste) and wipe clockwise with a soft cloth for 3-5 minutes to repair.

Application Scenario Segmentation:

Offline experience stores: Use "open glass display platforms" (glass thickness 12mm, load-bearing≥30kg) for customers to experience hands-on;

Mall counters: Use "closed glass cabinets" (with electronic locks) to prevent product loss, with "touch induction areas" on the glass door that automatically turn on internal lights when touched by customers.

7. Glass Display Cabinet Cleaning Tips

Cleaning is crucial for extending the service life of glass display cabinets and ensuring display effectiveness. Methods should be selected based on stain types and glass materials. The specific steps are as follows:

Daily Basic Cleaning (once a day):

Tools: Microfiber cloth (lint-free, scratch-free), neutral cleaner (such as dish soap, special glass cleaner);

Steps: First dilute the cleaner (1:20 ratio, water: cleaner), dip the cloth and wipe the glass in an "S-shaped" pattern to avoid back-and-forth wiping (preventing stain spread); wipe again with a dry cloth to eliminate water marks;

Applicable scenarios: Fingerprints, dust, minor water stains.

Stubborn Stain Treatment (once a week):

Oil stains (common in catering cabinets): Soak a soft cloth in warm water, dip in a small amount of baking soda (weakly alkaline, non-corrosive to glass), gently wipe the oil-stained area, then clean with water;

Adhesive residues (label residues): Cover the adhesive with an alcohol pad (75% concentration) for 30 seconds, wait for the adhesive to soften, then gently scrape off with a plastic scraper (avoid metal scrapers to prevent scratching);

Water scale (common in refrigerated cabinets): Wipe with diluted white vinegar solution (1:10), let it sit for 5 minutes, then clean with water. Avoid vinegar residue (which may corrode metal frames).

Cleaning Taboos for Special Materials:

Anti-fingerprint glass: Do not use alcohol or ammonia-containing cleaners (which may damage the anti-fingerprint film); only use neutral cleaners;

Coated glass: Do not use steel wool or hard brushes (which may scratch the coating); clean with light force;

Laminated glass: Prevent cleaners from seeping into the interlayer (if there are gaps at the glass edges, seal with sealant after cleaning).

Precautions: Turn off the power during cleaning (especially for cabinets with LED lights and refrigeration functions); Use cotton swabs dipped in cleaner to wipe glass corners (where dust easily accumulates); After cleaning, check the connection between glass and frame;wipe dry

any cleaner residue to prevent metal frame rusting.

8.Safety Guidelines for Glass Display Cabinets

Safety hazards of glass display cabinets mainly come from "glass breakage", "cabinet tipping", and "electrical faults" (for cabinets with functional modules). These should be avoided from three aspects: installation, use, and maintenance:

(1)Installation Safety (Core Points):

Floor requirements: Must be level (error≤2mm). If the floor is uneven, use metal shims (1-3mm thick) for adjustment to prevent cabinet tilting;

Fixing method: Floor-standing glass cabinets with height≥1.8m must be fixed to the wall with expansion screws (especially in high-traffic areas such as shopping malls and schools) to prevent tipping;

Load-bearing test: After installation, conduct a load-bearing test (place 80% of the rated load on the bottom layer, let stand for 24 hours; qualified if no deformation or cracking occurs).

(2)Usage Safety (Daily Standards):

No overloading: The load on each glass shelf must not exceed the rated value (e.g., 5mm glass≤10kg, 8mm≤20kg). Avoid placing heavy objects (such as dumbbells, large appliances);

Avoid sudden temperature changes: Glass has a temperature resistance range (e.g., tempered glass -40℃-280℃). Do not directly expose cold glass刚 taken from the refrigerator (-10℃) to hot water (above 80℃), which may cause cracking;

Anti-collision: Attach "anti-collision strips" (such as silicone strips, 5mm thick) to cabinet corners, especially in children's activity areas, to reduce collision injuries.

(3)Electrical Safety (for cabinets with functional modules):

Power requirements: Must use grounded sockets (to prevent electric leakage). Wires should be hidden inside the cabinet to avoid exposure (preventing customer tripping);

Regular inspection: Check wire connections of LED lights and refrigeration systems every 2 months; replace immediately if loose or aged;

Fault handling: If electric leakage occurs (tingling sensation when touching the cabinet), immediately cut off power and contact professional maintenance personnel; do not disassemble by yourself.

9.User Guide for LED Lighting and Temperature Control Functions of Smart Glass Display Cabinets

With the development of intelligence, glass cabinets with LED lighting and constant temperature control have become mainstream. Proper operation of these functions can enhance display effect

and reduce energy consumption:

1.LED Lighting System Operation

Brightness adjustment: Adjust according to product type—70%-80% brightness for jewelry and cultural creative products (to highlight details), 50%-60% brightness for cold foods (Gelato, sushi) (to avoid products appearing "old" under strong light). Some smart cabinets support "timed dimming" (e.g., automatically brighten 30 minutes before opening, turn off after closing), which can be set via mobile APP;

2.Color temperature selection

Warm light (3000K-4000K) is suitable for food and wooden products (enhancing warmth); cool light (5000K-6500K) is suitable for electronic and metal products (highlighting technological sense). Avoid mixing color temperatures (prone to visual confusion);

Maintenance points: LED lights have a service life of approximately 50,000 hours. If lights flicker or brightness decreases, replace the entire light strip (do not replace single bulbs, which may cause uneven brightness). Power off before replacement to avoid electric shock.

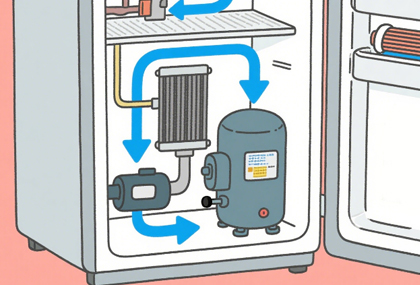

3.Constant Temperature Control Operation (catering, medical scenarios)

Temperature setting: Gelato cabinets: -12℃to -18℃; cake cabinets: 2℃-8℃; medicine refrigerators: 2℃-10℃. After setting, calibrate with a thermometer (place thermometer inside the cabinet, compare display temperature after 24 hours; qualified if error≤1℃);

Energy consumption control: Avoid frequent door opening (each opening causes temperature to rise by 2℃-3℃, increasing cooling load). It is recommended to stick "open and close gently" reminders on the door. During non-business hours at night, activate "energy-saving mode" (temperature increased by 2℃, e.g., cake cabinet from 5℃to 7℃), reducing energy consumption by 30%;

Fault handling: If temperature display is abnormal (e.g., set to 5℃but actual 10℃), first check if the door is tightly closed (whether the sealing strip is aged), then clean the condenser filter (excessive dust affects heat dissipation). If still abnormal, contact after-sales to inspect the compressor.

10. Customized Display Cabinet Design: How to Match Different Scenario Requirements

Different industries and products have significant differences in requirements for glass display cabinet size, structure, and functions. Customization should follow the principle of "scenario adaptation + cost control". The specific process is as follows:

(1)Requirement Clarification Stage

①Core parameter confirmation: Product size (determines internal shelf spacing), load-bearing requirements (determines glass thickness), environmental conditions (room temperature/refrigerated/humid, determines glass temperature resistance), display method (open/closed/semi-open);

②Case reference: For example, pet stores displaying live hamsters need customized "glass cabinets with ventilation holes" (5mm aperture to prevent escape), with built-in constant temperature lights (temperature 25℃±2℃); clothing stores displaying accessories (scarves, hats) customize "multi-layer rotating glass cabinets" (360°rotation to improve display efficiency).

(2)Design Communication Points

Material selection: Clearly specify glass type (e.g., ultra-clear/tempered/laminated) and frame material (aluminum alloy/carbon steel/solid wood) with the manufacturer; request material test reports (e.g., 3C certification for tempered glass);

①Function integration: If adding LED lights, specify light strip position (top/side/bottom), color temperature, and brightness adjustment method; if requiring refrigeration, confirm cooling method (direct cooling/fan cooling; fan cooling is more uniform, suitable for products requiring uniform temperature control such as Gelato);

②Size error: Custom size error should be≤3mm (especially for embedded glass cabinets, which need to fit walls and floors). Specify error range and compensation clauses in the contract.

(3)Acceptance Criteria

①Appearance: Glass free of scratches, bubbles, and impurities; frame free of deformation and paint peeling;

②Function: LED lights with uniform brightness and no flicker; temperature control function with temperature fluctuation≤1℃within 24 hours;

③Safety: Firm connection between glass and frame; no looseness when shaking the cabinet; floor-standing cabinets fixed to the wall.

11.Common Fault Troubleshooting

In daily use, glass display cabinets may encounter issues such as glass cracking, LED lights not working, and temperature control failure. Mastering basic troubleshooting methods can reduce losses:

(1)Glass Cracking/Breaking

Minor cracking (crack≤5cm): Immediately remove products from the cabinet, seal the crack with transparent tape (to prevent expansion), contact the manufacturer for glass replacement, and do not use the cabinet before replacement;

(2)Severe breakage (glass scattering)

If it is laminated glass (does not scatter when broken), cover the glass surface with cardboard (to prevent scratches) and wait for professional replacement; if it is ordinary tempered glass, first clean scattered particles (use a vacuum cleaner), then replace.

(3)LED Lights Not Working

Check power supply: Confirm the socket is powered, and whether wire connectors are loose (open the cabinet back cover and re-plug the connectors);

Replace accessories: If a single LED bulb is not working, replace the light strip (purchase the same model, replace after powering off); if all lights are not working, check the transformer (measure voltage with a multimeter; replace if no voltage).

(4)Temperature Control Failure (Refrigerated Cabinets)

Preliminary inspection: Check if the cabinet door is tightly closed (whether the sealing strip is aged; replace if aged), and if the condenser filter is blocked (clean dust);

Professional handling: If failure persists after inspection, it may be a compressor fault. Do not disassemble by yourself; contact after-sales service (compressor warranty is usually 3 years).

(5)Cabinet Tilting:

Adjust foot pads: Floor-standing cabinets usually have adjustable foot pads. Rotate clockwise to raise, counterclockwise to lower, and adjust until the cabinet is level (use a level tool);

Wall fixing: If tilting persists after adjustment, re-fix to the wall with expansion screws to ensure the cabinet fits the wall.

Precautions: Always power off before troubleshooting (especially for electrical faults); keep photos of the fault to help the manufacturer diagnose; when replacing glass, use the same model and thickness to avoid installation difficulties due to size mismatch.

12.Placement Principles: How to Enhance Display Effect Through Layout

Reasonable placement can not only highlight products but also optimize space flow. It should integrate three principles: "visual focus", "customer flow", and "product association":

Visual Focus Principle:

Height adaptation: The golden display area is 1.2m-1.6m (easily visible at eye level), where main products are placed (e.g., signature Gelato flavors, new jewelry collections); products above 1.6m are secondary, and those below 1.2m are stock or promotional items;

Light and shadow coordination: Place products in direct LED light areas (avoid shadow coverage). For example, diamond jewelry under direct top light to highlight fire, and cake cream patterns under side light to enhance layering.

Customer Flow Principle:

Aisle reservation: Maintain aisle width≥1.2m between glass display cabinets (to allow two people to pass side by side) to avoid congestion;

Entrance guidance: Place "open glass cabinets" at store entrances (e.g., catering sample displays) to attract customers; place "closed glass cabinets" (e.g., high-end products) deeper inside to引导 customers further into the store.

Product Association Principle:

Category concentration: Place products of the same category in one glass cabinet (e.g., fruit-flavored Gelato in one cabinet, nut-flavored in another) for easy customer selection;

Matching display: For example, in electronic product display cabinets, place mobile phones with matching headphones and chargers on the same shelf to promote associated sales; in catering cabinets, place cakes with matching tableware on adjacent shelves to enhance consumption experience.

Application case: Dessert shop layout—Place an "open ultra-clear glass platform" at the entrance (displaying daily fresh cake samples), and a "vertical refrigerated glass cabinet" against the inner wall (storing Gelato, 10mm glass thickness with anti-fog function). Inside the cabinet, partition by "fruit-based→nut-based→classic flavors", with corresponding flavor labels on each shelf (labels attached to the outer glass to avoid blocking products). Use 3500K warm LED lights on top to enhance appetite appeal of desserts.

13. Maintenance Myths: These Wrong Operations Will Shorten Glass Display Cabinet Lifespan

In daily maintenance, many people damage glass cabinets due to improper operations. Below are common myths and correct practices:

Myth 1: Cleaning all glass with alcohol

Reason for error: Alcohol corrodes anti-fingerprint films and coatings, causing glass to lose functionality;

Correct practice: Use neutral cleaners for anti-fingerprint and coated glass; ordinary glass can occasionally be cleaned with alcohol (no more than once a month).

Myth 2: Overloading glass shelves

Reason for error: Long-term overloading causes glass fatigue and cracking (even tempered glass has load limits);

Correct practice: Control load by glass thickness (5mm≤10kg, 8mm≤20kg, 10mm≤30kg). Place heavier items on the bottom and lighter ones on upper shelves.

Myth 3: Not defrosting refrigerated glass cabinets

Reason for error: Frost layer exceeding 10mm reduces refrigeration efficiency, increases energy consumption, and causes excessive temperature differences leading to glass cracking;

Correct practice: Defrost once a week. Power off, open the door, let frost melt naturally (avoid pouring hot water to prevent thermal shock cracking), and dry with a cloth.

Myth 4: Not protecting glass corners

Reason for error: Glass corners are stress concentration points; collisions easily cause cracking, and long-term neglect increases breakage risk;

Correct practice: Attach silicone anti-collision strips to cabinet corners (especially in child-accessible areas), and wrap corners with foam during transportation.

Myth 5: Not checking sealing strips

Reason for error: Aged sealing strips cause cold air leakage (increasing energy consumption by 20%) and dust entry, contaminating products;

Correct practice: Inspect strips every 3 months. Replace immediately if hardened or cracked (purchase the same model, cut to length, and apply a small amount of glue when pasting).

14.Adaptation Solutions for Low-Temperature and Humid Environments

In low-temperature (e.g., cold storage, northern winter stores) and humid (e.g., southern rainy seasons, seafood stores) environments, glass display cabinets require special adaptation to prevent issues like glass cracking and cabinet rusting:

(1)Low-Temperature Environments (Temperature≤0℃)

Material selection: Use low-temperature resistant tempered glass (temperature resistance -60℃-280℃to avoid embrittlement) and 304 stainless steel frames (corrosion-resistant, avoiding carbon steel rust);

Functional configuration: Install a "glass anti-fog system" (e.g., electric heating wires, temperature 50℃±5℃to prevent frosting), and set "anti-freeze foot pads" at the bottom (10mm thick to avoid direct contact with cold floors);

Usage Points: Preheat the cabinet before use (e.g., adjust refrigerated cabinets from -20℃to -15℃and preheat for 30 minutes) to avoid sudden temperature changes; use warm water (20℃-30℃) for cleaning, never cold water (which may cause glass cracking due to excessive temperature difference).

(2)Humid Environments (Humidity≥70%)

Material selection: Use laminated glass (to prevent humid air from entering the interlayer and causing fogging), and aluminum alloy frames (with anodized surface treatment, better moisture resistance than stainless steel);

Functional configuration: Install a "dehumidification module" (e.g., small dehumidifier, humidity controlled at 50%±5%) in the cabinet, and attach "moisture-proof film" on the inner side of the glass (to reduce water vapor condensation);

Usage Points: Ventilate the cabinet daily for 10 minutes (to prevent moisture accumulation); regularly apply waterproof glue at frame joints (to prevent water from seeping in and causing screw rust); ensure glass and frame are completely dry after cleaning before closing the door.

(3)Special Scenario Case: Seafood Store Glass Display Cabinet

Adaptation Requirements: Moisture resistance and salt spray corrosion resistance (seafood moisture contains salt, which easily corrodes metal);

Solution: Use ultra-clear tempered glass (with salt spray-resistant coating), and 316 stainless steel frames (salt spray corrosion resistant, service life twice that of 304 stainless steel); open "drainage holes" at the bottom of the cabinet (with filters to prevent seafood residue blockage), and place "moisture-absorbing boxes" inside (replace once a week);

Usage Notes: After daily business, clean the cabinet with fresh water (to remove salt residue), dry the frame with a dry cloth to avoid long-term salt adhesion.

15. Practical Recommendations from Lighting to Storage

Suitable accessories can enhance the functionality and display effect of glass display cabinets. Below are accessory recommendations for different scenarios:

Lighting Accessories:

Embedded LED Light Strips: Suitable for internal cabinet lighting, thickness≤5mm, can be pasted under glass shelves or on frame sides, color temperature 3000K-6500K optional, suitable for all scenarios;

Track Spotlights: Suitable for open glass platforms, adjustable irradiation angle (0°-180°), highlighting individual products (e.g., jewelry, high-end cultural creations), power 10W-20W is sufficient to avoid glare;

Induction Lights: Suitable for closed glass cabinets, automatically turn on when customers approach (induction distance 0.5m-1m), energy-saving and enhancing interaction, suitable for mall counters.

Storage Accessories:

Transparent Acrylic Shelves: Freely adjustable height (adapting to different product sizes), lightweight (each≤500g), suitable for jewelry and accessory display;

Anti-Slip Mats: Silicone material, thickness 2mm-5mm, pasted on glass shelf surfaces to prevent product sliding (e.g., electronic products, ceramics), available in transparent or white, without affecting display;

Rotating Trays: Suitable for circular glass cabinets, 360°rotatable (rotation speed 5r/min), increasing product display surface, suitable for small cultural creations and handcrafted products.

Functional Accessories:

Electronic Labels: Pasted on the outer side of glass, displaying product name, price, and material (supporting wireless updates), suitable for retail scenarios to reduce paper label waste;

Smart Locks: Supporting password, NFC, and APP unlocking, suitable for high-end product display (e.g., jewelry, luxury goods), can record unlocking records for easy management;

Hygrometers/Thermometers: Embedded design, installed inside the glass cabinet, displaying real-time environmental parameters (accuracy±1℃/±5% RH), suitable for environment-sensitive products such as intangible cultural heritage items and pharmaceuticals.

Matching Principles: Do not use excessive accessories (no more than 3 types per cabinet) to avoid overshadowing the products; colors should be mainly transparent, white, or silver to coordinate with glass materials; functional accessories must be compatible with the cabinet (e.g., confirm cabinet thickness for smart locks, voltage for light strips).

16. Core Value and Selection Recommendations for Glass Cabinets

As a "visual bridge" in commercial scenarios, the core value of glass display cabinets lies in amplifying product advantages through "transparent display" while extending product lifespan through "safety protection". From material selection to scenario adaptation, from daily maintenance to intelligent upgrades, every link must focus on "product characteristics" and "user needs"—retail jewelry requires priority attention to high-transparency glass and scratch resistance, catering cold food needs to focus on low-temperature resistance and anti-fog design, and cultural heritage items need to balance constant temperature and humidity with UV protection.

In the selection and use process, remember three core principles: First, "material adaptation to scenarios"—select tempered, ultra-clear, or laminated glass based on environmental temperature, humidity, and product characteristics to avoid safety hazards from improper materials; second, "maintenance over repair"—extend equipment life and reduce failure rates through daily cleaning and regular inspection of sealing strips and connections; third, "functions serve display"—functions like LED lighting and intelligent temperature control should focus on "enhancing product visual effect

" rather than blindly pursuing multiple functions.

In the future, with the deepening trends of "green consumption" and "smart experience", glass display cabinets will develop towards "thinner, more energy-efficient, and smarter" directions, such as adopting ultra-thin flexible glass (thickness≤2mm), solar power modules, and AI visual recognition (automatically counting customer-focused products). For practitioners, mastering the essence of using glass display cabinets can not only enhance product competitiveness but also take the initiative in visual marketing, allowing each product to convey unique value and charm through the "perspective" of glass.

Most popular More «

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?

-

Ideal temperature and temperature control points of cake cabinet

-

Which Cooluma compact commercial cake display cabinet is the best?