Comprehensive Maintenance Guide for Cooluma Countertop Food Display Cabinets

Countertop food display cabinets are used for storing and displaying foods such as cakes, desserts, and coffee. They usually adopt glass material to enhance the visual effect of the equipment. In terms of functionality, the temperature control (usually 2-8℃) inhibits bacterial reproduction and extends the shelf life of food. The closed design reduces the risk of cross-contamination and complies with food safety regulations. Of course, mastering the maintenance principles is also very important.

I. General Maintenance Principles for Countertop Display Cabinets

1. Cleaning Guidelines

- Prohibited Items: Steel wool pads, alkaline cleaners, alcohol, boiling water, oil-based solvents

- Recommended Items: Neutral detergent (e.g., diluted dishwashing liquid), soft cloth, sponge, glass cleaner

- Procedure: Disconnect power → Wipe exterior → Clean interior → Disinfect → Dry → Reconnect power

2. Operational Maintenance

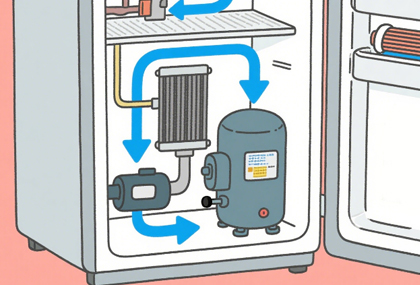

- Avoid frequent power cycling (compressor has 2-minute delay protection)

- Ensure adequate ventilation: ≥10cm clearance from wall at rear, sufficient space above

- Regularly check voltage (recommended range: 187-242V; use voltage stabilizer during fluctuations)

II. Specific Maintenance Guidelines for Various Display Cabinets (Using Cooluma Brand as Example)

1. Cake Refrigerator

Temperature Management:

- Set to 2-8°C (36-46°F) with humidity controlled at 50%-70% to prevent cakes from drying out or becoming damp

- Allow new cakes to cool completely before placing them inside to avoid condensation affecting decorations

Special Care:

- Store decorated cakes in sealed containers or loosely covered with plastic wrap to prevent direct contact with cabinet walls

- Regularly check defrost function (manual defrost required when evaporator frost ≥5mm)

- Unplug during extended storage; thoroughly clean, dry, and seal before storage

2. Dessert Display Cabinet

Storage Tips:

- Store different desserts in separate zones to prevent flavor transfer (advantage of multi-tiered shelf design)

- Store cheese products separately in airtight containers

Cleaning Focus:

- Thoroughly clean interior shelves at least once weekly to prevent sticky residue like syrup buildup

- Regularly sanitize with food-grade disinfectant to eliminate lingering odors

3. Cooked Food Heating Display Cabinet

Temperature Control:

- Set between 60-85°C (adjust based on food type) to ensure food safety

- Regularly calibrate the thermostat to prevent excessive temperature fluctuations

Maintenance Guidelines:

- Use stainless steel-specific cleaners to prevent corrosion of heating elements

- Exercise extreme caution around heating elements and temperature probes during cleaning to avoid damage

- Inspect heating element connections for looseness and tighten promptly

4. Coffee Cabinet

Cleaning Protocol:

- Daily removal of coffee stains to prevent penetration into cabinet structure (use neutral cleaner + soft cloth)

- Regular inspection of lighting system to ensure optimal display effect

Special Maintenance:

- Regularly clean and sanitize coffee grounds containers to prevent mold growth

- If also used for refrigeration, maintain per refrigerator standards; if solely for display, keep interior dry

5. Ice Cream Cabinet

Temperature Management:

- Set freezer display cabinets below -18°C to maintain ice cream hardness

- Regularly inspect refrigeration systems to prevent temperature fluctuations causing ice cream to melt and refreeze

Cleaning Procedure:

- Disconnect power before cleaning; wait until interior temperature rises to near room temperature before proceeding

- Thoroughly clean interior with warm water + neutral detergent, paying special attention to hard-to-reach areas like paddle connections

- All components must be completely dry after cleaning to prevent ice damage

- Ensure door gaskets are dry before restarting to avoid sticking

III. Cooluma Display Cabinet Maintenance Schedule

Daily Maintenance

| Item | Action | Notes |

|---|---|---|

| External Cleaning | Wipe cabinet surfaces and glass with a slightly damp cloth to remove fingerprints and stains | Avoid using alcohol-based glass cleaners to prevent damage to cabinet materials |

| Internal Inspection | Clean food residue and check that drain holes are unobstructed | Immediately remove any standing water to prevent bacterial growth |

| Door Gasket Maintenance | Wipe seals with a dry cloth to ensure no food particles remain | Avoid using grease-based cleaners to prevent rubber deterioration |

| Temperature Monitoring | Check display temperature is within set range | Record abnormal fluctuations and contact after-sales service |

Weekly Maintenance

| Item | Action | Method |

|---|---|---|

| Deep Cleaning | Power off and thoroughly clean all interior and exterior surfaces, including shelves and lampshades | Use neutral detergent + warm water. After complete disinfection, wipe with clean water. Power on only after full drying |

| Condenser Dust Removal | Clean dust from ventilation openings and condenser surface | Use vacuum cleaner or soft-bristle brush to carefully remove dust, preventing damage to fins |

| Drainage System Maintenance | Inspect and clean drain channels and pipes | Prevent leaks caused by blockages |

| Door Seal Inspection | Use the “dollar bill test” to check seal effectiveness (bill should be difficult to pull out after door closes) | If seal is compromised, contact service immediately to replace door gasket |

Monthly Maintenance

| Item | Action | Professional Tip |

|---|---|---|

| Filter Cleaning | Clean dust filters (if applicable) and ventilation filters | Improve airflow efficiency and reduce energy consumption |

| Lubricate Moving Parts | Apply appropriate amount of food-grade lubricant to slides and hinges | Reduce friction and noise, extend service life |

| Temperature Control Calibration | Verify display accuracy using standard thermometer | Adjust or repair if error exceeds ±1°C |

| Lighting system inspection | Replace damaged lighting fixtures to ensure optimal display | Select appropriate color temperature for different foods (e.g., warm light for cakes) |

Quarterly Maintenance

| Item | Action | Technical Points |

|---|---|---|

| Comprehensive Refrigeration System Inspection | Check compressor operating status and refrigerant pressure | Listen for smooth operation without abnormal vibrations or noise |

| Electrical System Maintenance | Inspect wiring connections for looseness or damage | Prevent electrical leakage risks and ensure safe operation |

| Seal Performance Testing | Thoroughly inspect all gaskets; replace as necessary | Aged gaskets can increase energy consumption by over 20% |

| Defrost System Inspection | Test automatic defrost function (refrigerators) | Record next frosting time after manual defrost to evaluate system efficiency |

Semi-Annual Maintenance

| Item | Action | Recommendation |

| Deep Condenser Cleaning | Dismantle and thoroughly clean condenser and evaporator | Improves cooling efficiency, reduces energy consumption by approximately 15% |

| Comprehensive Disinfection | Disinfect interior using food-grade disinfectant | Pay special attention to corners and seams to prevent bacterial growth |

| Performance Testing | Full-load operation test to evaluate cooling/heating efficiency | Record cooling/heating cycle times and compare against manual specifications |

| Professional Maintenance | Contact Cooluma official after-sales for professional inspection | Ensure critical components function properly and obtain maintenance records |

IV. Long-Term Deactivation and Restart Guide

Deactivation Steps:

1. Shut down the refrigeration system 24 hours in advance and remove all food items

2. Thoroughly clean all interior and exterior surfaces, disinfect, and ensure complete drying

3. Unplug the power cord and leave the door slightly open (to prevent odors and mold)

4. For long-term storage, cover with a dust cover and avoid direct sunlight

Restart Procedure:

1. Clean the exterior and inspect for damage

2. Verify voltage stability before powering on

3. Run empty for 1-2 hours. Only place food inside after confirming normal cooling/heating

4. Add food gradually to avoid disrupting temperature stability

V. Maintenance Precautions Summary

✓ Mandatory Tasks:

- Disconnect power before cleaning to ensure personal safety

- Use mild detergents to protect cabinet materials

- Regularly inspect and maintain door seals (critical for energy efficiency)

- Record each maintenance date to establish a maintenance log

✗ Prohibited Actions:

- Avoid using sharp tools for cleaning to prevent scratching glass and cabinet surfaces

- Do not use strong alkaline/acidic cleaners, as they corrode materials

- Never block ventilation openings, as this causes overheating and equipment damage

- Frequent power cycling shortens compressor lifespan

⭐ Practical Tips:

- Glass Cleaning: Spray a small amount of glass cleaner onto a soft cloth; avoid direct spraying on glass (to prevent liquid seepage)

- Odor Control: Place activated charcoal packets or lemon slices inside the cabinet; replace regularly to maintain fresh air

Adhering to the principle of “Clean, Stabilize, Inspect, Maintain” and following the above schedule for regular upkeep will not only extend the lifespan of your Cooluma display cabinet but also ensure food safety and enhance presentation quality. Remember: Good maintenance habits are more economical and reliable than repairs after breakdowns! We recommend posting this schedule near the equipment for daily reference, keeping your display cabinet in optimal condition at all times.

Most popular More «

-

Comprehensive Maintenance Guide for Cooluma Countertop Food Display Cabinets

-

How to solve the core pain points countertop display cases of bakery stores?

-

What is the price of a cake display cabinet in Mumbai?

-

Review of Pastry Countertop Display Cabinet T90C/T90S

-

What techniques are crucial for quality in glass cabinet manufacturing?

-

What are the models available for the Cooluma bread refrigerator with two shelves?

-

The Best Manufacturer of Commercial Italian Gelato Cabinets - Cooluma

-

What is the difference between 5 cake cabinets?

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers