Does the GN series gelato display cabinet frost?

In the field of commercial refrigeration, frost formation in gelato display cabinets is a critical factor affecting product presentation and energy efficiency. For the GN series gelato display cabinet, its structural design and integrated refrigeration technologies effectively mitigate frost issues. Here’s a technical analysis of its anti-frost mechanisms:

1. High-airtight sealing structure: Blocking moisture intrusion

Frost formation primarily stems from heat and mass exchange between moist air and low-temperature surfaces. When ambient air with high humidity infiltrates the cabinet, water vapor comes into contact with internal surfaces or gelato (maintained at -15℃ to -25℃) and undergoes supersaturation, leading to either direct deposition (sublimation into frost) or condensation-freezing (liquefaction followed by solidification into ice).

The GN series features a mortise-tenon joint structure between the glass cover and cabinet body, paired with EPDM (Ethylene Propylene Diene Monomer) gaskets. This design achieves Class Ⅱ airtightness standards for commercial refrigeration equipment (air leakage rate ≤0.5 m³/(h·m)), significantly reducing the infiltration of external moist air. By minimizing the "moisture load" inside the cabinet, it fundamentally lowers the potential for frost formation.

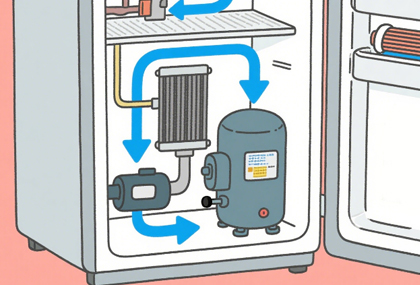

2. Optimized airflow organization and refrigeration system matching

The cabinet adopts a bottom return air + dual-side top supply air pattern, combined with a variable-diameter air duct design, creating a "piston flow" circulation of cold air. This airflow configuration offers two key advantages:

- Temperature field uniformity: Through CFD (Computational Fluid Dynamics) simulation optimization, the temperature standard deviation inside the cabinet is controlled within ±0.8℃, eliminating "cold spots"—localized overcooled areas where water vapor tends to rapidly sublimate into frost. A uniform temperature field inhibits initial frost crystal formation.

- Moisture removal efficiency: Circulating cold air promptly carries away water vapor from gelato sublimation or residual moisture inside the cabinet to the return air inlet. This moisture is first condensed (or sublimated) on the evaporator’s low-temperature surface and then removed through defrosting procedures, reducing frost accumulation on internal walls.

The evaporator employs a finned tube + hydrophilic aluminum foil structure. The hydrophilic coating allows condensed water to quickly coalesce into droplets and drain away, preventing frost formation on fin surfaces and maintaining low humidity in the cold air, further reducing frost risks.

3. High-efficiency insulation and precise temperature control

The cabinet’s insulation layer uses polyurethane (PU) foam with a density of 45 kg/m³ and a thermal conductivity ≤0.024 W/(m·K), forming a high-resistance thermal barrier. This stabilizes the temperature difference (ΔT) between the inner and outer cabinet walls, avoiding "secondary condensation-frosting" caused by wall temperature fluctuations.

Additionally, the temperature control system integrates a PT100 platinum resistance sensor with a PID (Proportional-Integral-Derivative) algorithm, restricting temperature fluctuations to ±0.5℃. A stable low-temperature environment reduces "temperature-driven" water vapor phase changes (sudden temperature drops accelerate water vapor freezing), thermally suppressing frost formation.

4. Synergistic effect of implicit defrosting technology

Though not visually apparent, the GN series likely incorporates a timed electric heating defrost system. Heating elements attached to evaporator fins or critical low-temperature components activate preset defrost cycles (typically every 8–12 hours, lasting 10–15 minutes) to melt accumulated frost. This "preventive defrosting" works in tandem with the aforementioned structural designs, keeping frost at an "invisible" or "ultra-thin" state, reinforcing the perception of "low frost formation."

In summary, the GN series gelato display cabinet minimizes frost through a multi-dimensional integration of sealing, airflow, insulation, temperature control, and defrosting technologies. While absolute frost-free operation is physically challenging (due to inevitable moisture and low-temperature interactions), its design effectively controls frost to negligible levels, ensuring optimal gelato presentation and operational efficiency.

Most popular More «

-

Why Are All-Glass Display Cases So Expensive?

-

Technical Parameters and Solutions for Commercial Cake Chillers

-

Coffee Display Equipment Full Dimension Strategy

-

Cooluma Best Countertop Cake Refrigerator

-

Commerical Bread Cabinet First-Time Use Step-by-Step Guide

-

How to choose a desktop cake supplier?

-

Ideal temperature and temperature control points of cake cabinet

-

Which Cooluma compact commercial cake display cabinet is the best?

-

What are the procedures required for the certification of food display cabinets?

-

Aims to be a global supplier of commercial cold chain equipment, Cooluma